Quick Summary

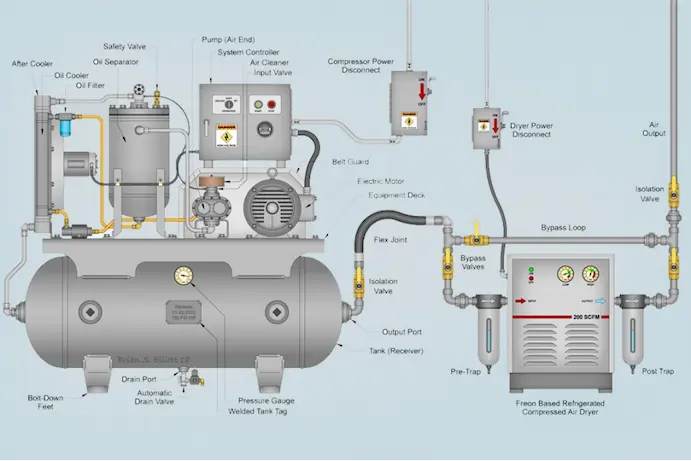

Compressed air is one of the most expensive energy sources in industrial plants, yet it is often treated casually. Valve selection plays a critical role in system efficiency, leakage control and long-term reliability. Ball valves, known for their tight sealing and minimal pressure drop, have become the preferred solution for compressed air systems. At Vcore Valve, we design ball valves specifically to meet the demanding requirements of modern pneumatic networks.

A Familiar Workshop Scenario

“Why does the compressor keep running even when production stops?”

“Because compressed air is leaking—silently, constantly, and expensively.”

Key User Pain Points

Invisible Energy Loss from Air Leaks

Even minor valve leakage can lead to significant compressor energy waste.

Pressure Drop Reducing Tool Performance

Poor valve design restricts airflow and lowers end-use pressure.

Frequent Maintenance and Downtime

Incompatible materials and weak seals fail quickly in compressed air service.

Practical Solutions from Vcore Valve

Use Tight-Sealing Ball Valves

Ball valves provide bubble-tight shut-off, critical for air systems.

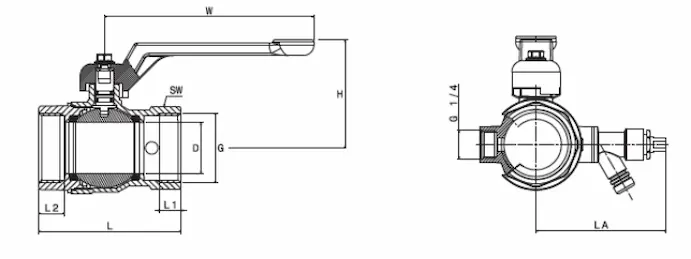

Select Full Bore Designs

Maintaining airflow reduces compressor workload.

Choose Materials Designed for Air Service

Proper seats and surface finishes extend service life.

Why Ball Valves Excel in Compressed Air Systems

Unlike liquids, compressed air is highly sensitive to leakage and pressure loss. our ball valve for compressed air offers a near-straight flow path and excellent sealing, making it ideal for pneumatic networks.

Key advantages include:

-

Extremely low leakage rates

-

Minimal pressure drop

-

Fast quarter-turn operation

-

High durability under frequent cycling

These characteristics directly support compressed air efficiency.

Leakage: The Silent Energy Killer

Studies show that compressed air leaks can waste 20–30% of total system energy. Traditional valves with multiple sealing surfaces struggle to maintain tight shut-off over time.

Ball valves, by contrast, rely on a single rotating sphere and resilient seats, making them one of the most low leakage valve options available.

Full Bore vs Reduced Bore in Air Systems

| Valve Design | Airflow Restriction | Energy Impact |

|---|---|---|

| Full bore ball valve | Minimal | Excellent |

| Reduced bore ball valve | Moderate | Acceptable |

| Globe valve | High | Poor |

For main air distribution lines, Vcore Valve strongly recommends full bore compressed air ball valves.

Case Study: Automotive Assembly Plant

An automotive factory experienced frequent pressure drops at pneumatic tools.

Problem:

-

Mixed valve types across air headers

Solution:

-

Replaced isolation valves with Vcore Valve full bore ball valves

Results:

-

Stable operating pressure

-

Reduced compressor cycling

-

Lower energy consumption by 15%

Scientific and Technical Analysis

Compressed air systems are highly sensitive to flow resistance:

-

Every 1 bar pressure drop increases compressor energy use by 7–8%

-

Ball valves typically exhibit significantly lower Cv loss than alternative valve types

-

Tight shut-off reduces compressor idle run time

These factors make ball valves for compressed air systems a strategic energy-saving component.

Market Trends and Industry Insight

-

Growing focus on compressed air audits

-

Rising demand for energy-efficient valves

-

Increased use of ball valves in smart pneumatic systems

-

Lifecycle cost replacing upfront price as key purchasing metric

Best Practices for Compressed Air Valve Selection

-

Use ball valves for isolation and zoning

-

Avoid unnecessary reducers and undersized valves

-

Select valves rated for high cycling

-

Inspect seals regularly to maintain leakage control

Conclusion

Compressed air is too valuable to waste. The right valve choice can dramatically reduce energy loss, improve system reliability and lower operating costs. Ball valves, with their tight sealing and low pressure drop, are the clear winner for compressed air systems.

At Vcore Valve, we supply industrial ball valves engineered for efficiency, durability and long-term performance in pneumatic applications.

👉 Contact Vcore Valve to optimise your compressed air system today.

FAQs

Q1: Are ball valves suitable for all compressed air pressures?

Yes, when correctly rated and selected.

Q2: Do ball valves reduce air leakage?

Yes, they offer superior sealing compared to many alternatives.

Q3: Is a full bore valve necessary for compressed air?

Highly recommended for main distribution lines.

Q4: Can ball valves handle frequent on-off cycling?

Yes, especially designs intended for pneumatic service.

Q5: How often should compressed air valves be inspected?

At least annually, or during energy audits.

Q6: Does Vcore Valve provide valves specifically for air systems?

Yes, tailored to industrial pneumatic applications.

Reference

NTGD Valve. Why Choose Ball Valves for Compressed Air Systems: Efficiency and Durability

Compressed Air & Gas Institute (CAGI). Compressed Air System Best Practices.

ISO 8573. Compressed Air Quality Standards.

Vcore Valve Engineering Guide. Valve Selection for Pneumatic Systems.v