Quick Overview

Our pneumatic butterfly valve combines a compact butterfly valve body with a pneumatic actuator to deliver fast, reliable, and repeatable flow control. Widely used in automation systems, these valves offer an excellent balance between performance, cost, and ease of maintenance. In this guide, Vcore Valve explains how pneumatic butterfly valves work, where they excel, and how to choose the right configuration for your process.

A Scene from the Plant Floor

“Manual operation is slowing us down.”

“Then it’s time for automation.”

That moment is often when engineers turn to air-operated butterfly valves—simple in principle, powerful in execution.

Common User Pain Points

Slow or Inconsistent Valve Operation

Manual valves or electric actuators may struggle in high-cycle or harsh environments.

High Maintenance Costs

Complex valve assemblies increase downtime and spare-part inventory.

Automation Compatibility Issues

Poor actuator matching leads to torque loss, vibration, or control failure.

Practical Solutions and Engineering Advice

Use Pneumatic Actuation for Speed and Reliability

Pneumatic butterfly valves deliver rapid open/close action with minimal mechanical complexity.

Match Actuator Torque Correctly

Selecting the right butterfly valve actuator prevents premature wear and ensures sealing integrity.

Choose the Right Body and Disc Design

Wafer, lug, or flanged styles should align with pipeline layout and maintenance needs.

What Is a Pneumatic Butterfly Valve?

Our pneumatic butterfly valve is an automated butterfly valve operated by compressed air. The actuator converts air pressure into rotary motion, turning the valve disc 90 degrees to control flow.

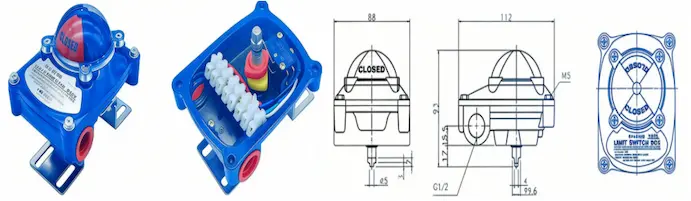

Key Components

-

Butterfly valve body

-

Disc and seat

-

Pneumatic actuator

-

Positioner or limit switch (optional)

This design makes it one of the most efficient process automation valves available today.

Types of Pneumatic Actuators

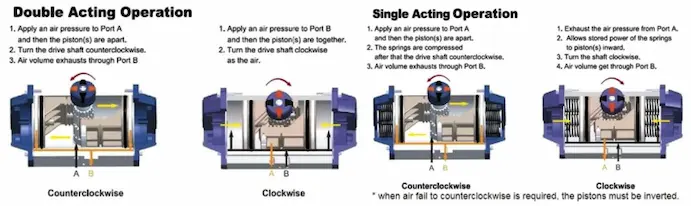

Double Acting Actuator

Uses air pressure to both open and close the valve. Ideal for continuous operation and precise control.

Spring Return Actuator

Uses air to open and a spring to close (or vice versa), providing fail-safe operation during air loss.

Vcore Valve offers both configurations to suit safety and process requirements.

Key Advantages of Pneumatic Butterfly Valves

Fast Response Time

Air actuation allows near-instant operation—critical in emergency shut-off scenarios.

Compact and Lightweight

Compared with gate or globe valves, industrial butterfly valves require less space and structural support.

Cost-Effective Automation

Lower initial cost and simpler maintenance compared with electric or hydraulic systems.

Excellent for High-Cycle Applications

Designed to withstand frequent operation without performance degradation.

Case Studies and Real-World Applications

Case 1: Water Treatment Facility

A municipal plant replaced manual valves with pneumatic butterfly valves to automate flow balancing.

Result:

-

40% reduction in operation time

-

Improved flow accuracy

Case 2: Chemical Processing Line

Corrosion-resistant air-operated butterfly valves were installed for batch processing.

Result:

-

Reliable shut-off

-

Reduced leakage incidents

Data and Engineering Comparison

| Valve Type | Response Speed | Maintenance | Automation Cost |

|---|---|---|---|

| Gate Valve | Slow | High | High |

| Globe Valve | Moderate | High | High |

| Ball Valve | Fast | Medium | Medium |

| Pneumatic Butterfly Valve | Very Fast | Low | Low |

This comparison explains why butterfly valves dominate modern automation systems.

Market Trends and Industry Insight

-

Increasing adoption of automated butterfly valves in water, HVAC, and energy sectors

-

Growth of Industry 4.0 is driving demand for smart valve accessories

-

Preference for pneumatic systems in hazardous areas due to intrinsic safety

-

Rising use of hydrogen-ready and low-emission systems

Selection and Usage Recommendations

-

Use wafer butterfly valves for compact piping systems

-

Choose lug butterfly valves where end-of-line service is required

-

Confirm actuator torque with a safety margin

-

Add positioners for modulating control

Conclusion

A pneumatic butterfly valve is a smart choice for industries seeking fast operation, reliable automation, and lower lifecycle cost. When properly selected and installed, it becomes a dependable workhorse in modern process control.

At Vcore Valve, we design and manufacture pneumatic butterfly valves tailored to real industrial demands—tested, certified, and ready for automation.

👉 Contact Vcore Valve today to discuss your pneumatic valve automation project.

FAQs

What air pressure is required for a pneumatic butterfly valve?

Typically 4–8 bar, depending on actuator design.

Are pneumatic butterfly valves suitable for throttling?

Yes, especially with positioners for precise control.

What industries commonly use these valves?

Water treatment, HVAC, chemical processing, oil & gas, and food industries.

Can they operate in hazardous environments?

Yes, pneumatic systems are ideal where electrical sparks must be avoided.

How long is the service life?

With proper selection and maintenance, over one million cycles is achievable.

Does Vcore Valve provide complete actuator assemblies?

Yes, valves are supplied fully assembled and tested.

References

-

ISO 5211 – Valve Actuator Interface

-

ASME B16.34 – Valve Pressure Ratings

-

IEC 60534 – Control Valve Standards

-

Valve Manufacturers Association (VMA)

-

Process Industry Practices (PIP)

-

Pneumatic Actuator Design Manuals