Quick Summary

Discussing single disc vs double disc gate valves is not just about structure—it directly affects sealing performance, operating torque, and long-term reliability. At Vcore Valve, we often see gate valve failures caused by incorrect disc selection rather than material or pressure rating issues. This guide explains how both designs work, where each excels, and how to select the right gate valve configuration for your system.

Opening Scenario: A Common Site Question

“Both are gate valves—why does one leak while the other works perfectly?”

This question comes up frequently during maintenance reviews. The answer often lies in whether the system uses a single disc gate valve or a double disc gate valve, and whether that choice matches the operating conditions.

User Pain Points

Unclear Structural Differences

Many buyers struggle to understand how disc design impacts sealing and operation.

Leakage After Installation

Improper disc selection can lead to poor sealing under low-pressure or thermal cycling conditions.

Over- or Under-Specifying Valves

Using complex designs where they are not needed increases cost without performance benefits.

Practical Solutions & Expert Advice

Match Disc Design to Operating Conditions

Pressure, temperature fluctuation, and line alignment all influence disc performance.

Understand Sealing Behaviour

Single and double disc designs seal differently under varying loads.

Focus on Lifecycle Cost, Not Just Price

A slightly higher upfront cost can significantly reduce long-term maintenance.

What Is a Single Disc Gate Valve?

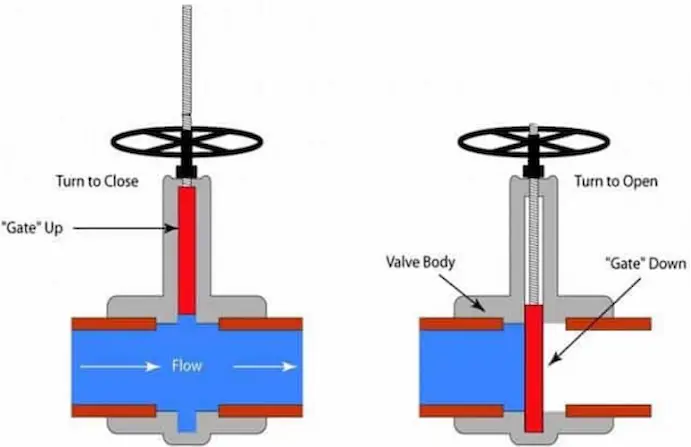

A single disc gate valve uses one solid wedge-shaped or parallel disc to block or allow flow. The disc moves vertically between the seats to achieve full open or full closed positions.

Common Single Disc Designs

-

Solid wedge gate valve

-

Flexible wedge gate valve

-

Split wedge (still classed as single disc)

These designs are valued for their simplicity and robustness.

What Is a Double Disc Gate Valve?

A double disc gate valve consists of two separate discs that expand outward against the valve seats, usually with a spreading mechanism or spring.

Typical Double Disc Configurations

-

Parallel double disc gate valve

-

Expanding gate valve

This design allows both discs to seat independently, improving sealing under low differential pressure.

Key Differences Between Single and Double Disc Gate Valves

Sealing Mechanism

-

Single disc gate valves rely on wedge force or line pressure for sealing

-

Double disc gate valves use mechanical expansion to achieve seat contact

Sensitivity to Pressure

Double disc designs perform better in low-pressure or bi-directional flow systems.

Alignment Tolerance

Double disc valves are more forgiving of minor pipeline misalignment.

Technical Comparison Table-Single Disc vs Double Disc Gate Valves

| Feature | Single Disc Gate Valve | Double Disc Gate Valve |

|---|---|---|

| Disc Structure | One solid disc | Two expanding discs |

| Sealing Method | Wedge force / pressure | Mechanical expansion |

| Low-Pressure Sealing | Moderate | Excellent |

| Bi-directional Flow | Limited | Excellent |

| Operating Torque | Lower | Slightly higher |

| Maintenance Complexity | Low | Medium |

| Typical Cost | Lower | Higher |

Case Study 1: Water Transmission Pipeline

A municipal water project initially installed single disc wedge gate valves. Under fluctuating pressure conditions, minor leakage occurred. After switching to double disc gate valves, sealing reliability improved significantly without changing materials or pressure class.

Case Study 2: Steam Distribution System

In a high-temperature steam line, single disc gate valves outperformed double disc designs due to simpler internals and reduced risk of thermal binding—highlighting that “better” always depends on application.

Engineering Analysis & Performance Considerations

From field data and factory testing at Vcore Valve, we observe:

-

Single disc valves perform best under stable pressure and temperature

-

Double disc valves reduce leakage risk by 20–30% in low-pressure systems

-

Thermal expansion affects wedge-type valves more significantly

-

Double disc designs require more precise machining and assembly

These factors must be considered during valve specification, not after installation.

Industry Trends & Market Insights

-

Water and wastewater sectors increasingly favour double disc gate valves

-

Oil & gas applications still prefer single disc wedge gate valves

-

Demand for bi-directional sealing is driving renewed interest in parallel gate designs

-

Buyers are shifting from price-driven to lifecycle-driven valve selection

Usage & Selection Tips from Vcore Valve

-

Use single disc gate valves for high-temperature or high-pressure systems

-

Choose double disc gate valves for low-pressure or frequent on/off service

-

Avoid double disc designs in dirty or slurry media unless specially designed

-

Always verify seat material compatibility with disc movement

Conclusion

Both single disc and double disc gate valves have proven reliability when applied correctly. The key lies in understanding how disc design interacts with pressure, temperature, and pipeline conditions. At Vcore Valve, we help customers move beyond catalogue comparisons to real engineering solutions.

👉 Contact Vcore Valve to get expert advice on selecting the right gate valve for your project.

FAQ

What is the main difference between single and double disc gate valves?

The difference lies in sealing method: single disc relies on wedge force, while double disc uses mechanical expansion.

Are double disc gate valves better than single disc ones?

Not always. Double disc valves excel in low-pressure or bi-directional applications, while single disc valves suit high-pressure and high-temperature systems.

Which gate valve has better sealing performance?

Double disc gate valves generally offer better sealing at low pressure.

Do double disc gate valves require more maintenance?

They have more internal components, which may slightly increase maintenance requirements.

Can single disc gate valves handle bi-directional flow?

They can, but sealing performance may be reduced compared to double disc designs.

Which industries commonly use double disc gate valves?

Water supply, wastewater treatment, and low-pressure pipeline systems.

Reference

-

JSC Valve Technical Centre. Structural and Performance Differences Between Single Disc and Double Disc Gate Valves in Industrial Applications. Industry technical article analysing disc design, sealing behaviour and application suitability.

-

API Specification 600. Steel Gate Valves — Flanged and Butt-Welding Ends. American Petroleum Institute standard outlining design principles, pressure classes and performance requirements for gate valves used in oil, gas and industrial service.

-

ISO 15761. Steel Gate Valves for Petroleum, Petrochemical and Allied Industries. International standard providing guidance on gate valve construction, testing and application limits.

-

The Engineering Toolbox. Gate Valves – Types, Design and Applications. Reference material covering wedge, parallel and expanding gate valve designs and their operating characteristics.

https://www.engineeringtoolbox.com/gate-valves-d_1450.html -

Vcore Valve Internal Engineering Notes. Field Experience on Gate Valve Selection, Sealing Performance and Failure Analysis. Compiled from project applications in water supply, energy, and industrial pipeline systems.