Quick Overview

In modern fluid control systems, 2-way and 3-way valves play fundamentally different roles. Yet many buyers treat them as interchangeable components, leading to inefficient flow control, unstable systems, and unnecessary costs. At Vcore Valve, we regularly help engineers and procurement teams clarify when a two-way valve is sufficient—and when a three-way valve is absolutely necessary. This guide explains the logic, applications, and selection principles behind both valve types.

Opening Scenario: A Common Engineering Debate

“Can’t we just use a 2-way valve here?”

“Yes—but then how do you divert or mix the flow?”

That single question often determines whether a system runs smoothly or becomes a constant troubleshooting exercise.

User Pain Points

Confusion About Valve Function

Many users understand valve size and material, but not port configuration logic.

Overcomplicated System Design

Using multiple 2-way valves where a single 3-way valve would be more efficient.

Control Instability

Incorrect valve selection can cause pressure spikes, temperature fluctuation, or uneven flow distribution.

Solutions & Expert Recommendations

Understand Flow Path Requirements

Valve necessity is defined by what the fluid must do, not just whether it must stop or start.

Reduce Components Through Smart Design

A properly selected 3-way valve can replace multiple isolation valves.

Choose Valves Designed for Control, Not Just Isolation

Control accuracy and response matter as much as shut-off capability.

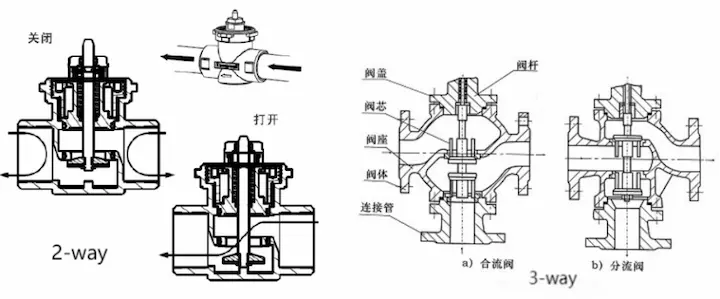

What Is a 2-Way Valve?

A 2-way valve has one inlet and one outlet. Its sole function is to allow or stop flow.

Typical Characteristics

-

On/off or throttling function

-

Simple structure

-

Lower cost and maintenance

-

Widely used in isolation duties

Common Applications

-

Water supply shut-off

-

Gas lines

-

Oil and chemical isolation

-

Simple process control loops

What Is a 3-Way Valve?

A 3-way valve has three ports and is designed to divert or mix flow.

Typical Characteristics

-

Flow diversion or mixing

-

Reduces piping complexity

-

Improves temperature and flow stability

-

Often used in control systems

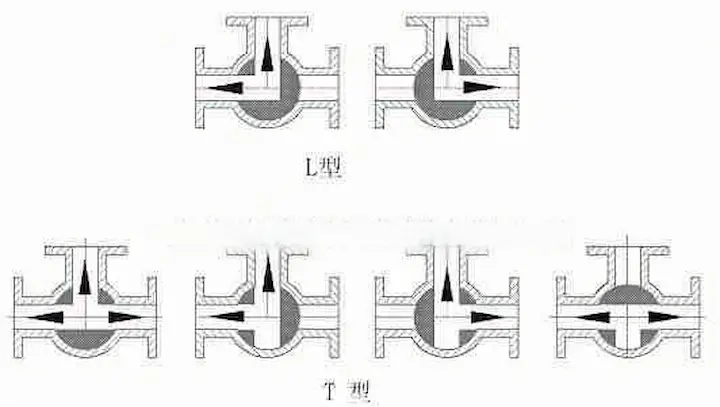

Common Configurations

-

L-port (diverting flow)

-

T-port (mixing or splitting flow)

2-Way Valve vs 3-Way Valve: Core Differences

| Feature | 2-Way Valve | 3-Way Valve |

|---|---|---|

| Number of Ports | 2 | 3 |

| Primary Function | Shut-off / regulate | Divert / mix |

| System Complexity | Simple | Moderate |

| Control Capability | Limited | High |

| Typical Use | Isolation | Process control |

Why 2-Way Valves Are Necessary

System Isolation

They remain the most reliable solution for complete shut-off.

Cost Efficiency

Fewer components and lower unit cost make them ideal for large-scale isolation.

Maintenance Simplicity

Straightforward design reduces failure points.

Why 3-Way Valves Are Necessary

Flow Direction Control

They enable seamless switching between two flow paths.

Temperature and Process Stability

Widely used in HVAC and heat exchange systems.

Reduced Piping and Valves

One 3-way valve can replace multiple 2-way valves.

Case Studies from Vcore Valve

Case 1 – HVAC Temperature Control

Replacing dual 2-way valves with a single 3-way mixing valve stabilised outlet temperature and reduced actuator failures.

Case 2 – Industrial Cooling Loop

A 3-way diverting valve simplified bypass control and improved energy efficiency.

Data & Engineering Considerations

-

3-way valves reduce pressure shock during switching

-

Fewer actuators mean lower automation cost

-

Proper port configuration prevents dead zones

Market Trends & Industry Insights

-

Increased use of 3-way valves in energy-efficient HVAC systems

-

Growing demand for automated control valves

-

Preference for compact valve solutions in modular skids

Usage & Selection Tips

-

Use 2-way valves for isolation and basic regulation

-

Use 3-way valves for mixing, diverting, or bypass control

-

Always confirm port configuration (L or T type)

-

Match actuator type to control accuracy requirements

Conclusion

Understanding why 2-way and 3-way valves are necessary is a matter of system logic, not valve preference. Two-way valves remain essential for isolation, while three-way valves unlock smarter flow management and control efficiency. At Vcore Valve, we help engineers select valves that simplify systems rather than complicate them.

FAQ

Q1: Can a 3-way valve replace two 2-way valves?

In many applications, yes—especially for diverting or mixing flow.

Q2: Are 3-way valves more expensive?

Per unit, yes—but they often reduce total system cost.

Q3: Do 3-way valves require special actuators?

Not necessarily, but actuator sizing is more critical.

Q4: Are 2-way valves suitable for control applications?

They can regulate flow but lack directional control.

Q5: Which valve is better for HVAC systems?

3-way valves are commonly preferred for temperature control loops.