Quick Summary

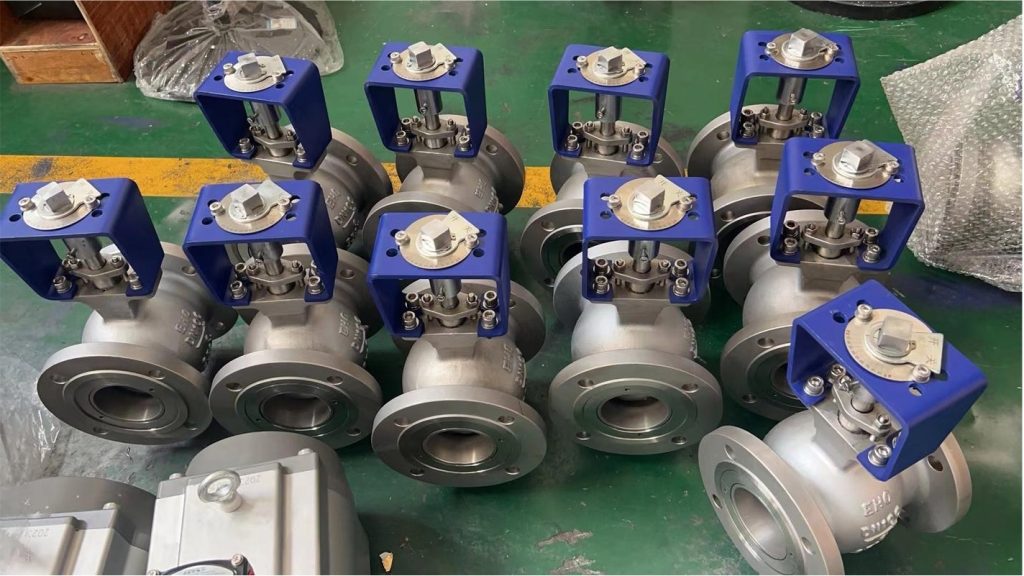

Electric Ball Valves have become indispensable in the chemical industry, combining robust construction with automated precision to handle corrosive, high-pressure fluids. Their reliability reduces downtime, enhances safety, and aligns with modern chemical processing demands for efficiency and compliance.

User Pain Points

Corrosion and Degradation from Aggressive Chemicals

Chemical processes often involve acids, alkalis, and solvents that eat away at traditional metal valves. Manual and even some pneumatic valves use seals and bodies made from non-resistant materials, leading to leaks within months.

Inconsistent Precision in Fluid Control

Many chemical reactions require exact flow rates and pressure adjustments. Manual valves rely on operator judgment, leading to human error, while older automated valves lack the responsiveness needed for dynamic processes.

High Maintenance and Downtime Costs

Traditional valves demand regular lubrication, seal replacements, and calibration. Each maintenance session requires shutting down a portion of the plant, with downtime costing chemical facilities up to £2,000 per hour, per the UK Chemical Industries Association.

Solutions & Recommendations

Choose Electric Ball Valves with Corrosion-Resistant Materials

Opt for Ball Valves constructed with 316L stainless steel bodies and PTFE seals—materials proven to resist 95% of common industrial chemicals. These valves form a barrier against corrosive fluids, extending service life from 6–12 months to 3–5 years.

Prioritize Automated Precision with Smart Electric Ball Valves

Select Electric Ball Valves equipped with servo motors and digital control systems. These valves respond to pressure and flow changes in 0.2 seconds—10x faster than manual valves—and maintain flow accuracy within ±1%.

Opt for Low-Maintenance Ball Valves with Modular Design

Sealed motors prevent chemical ingress, while modular designs let you replace parts without removing the entire valve from the pipeline. This cuts maintenance time by 70% and reduces downtime to under 30 minutes per repair.

Data & Scientific Analysis

Performance Comparison: Electric Ball Valves vs. Traditional Valves

| Metric | Electric Ball Valves | Manual Valves | Pneumatic Valves |

| Response Time | 0.2–0.5 seconds | 5–10 seconds | 1–2 seconds |

| Service Life | 3–5 years | 6–12 months | 1–2 years |

| Maintenance Cost/Year | £300–£500 | £1,200–£1,800 | £800–£1,200 |

| Flow Accuracy | ±1% | ±8–10% | ±3–5% |

Scientific Rationale for Electric Ball Valves in Chemicals

The ball design of Ball Valves minimizes fluid resistance, reducing pressure drops by up to 30% compared to gate valves. This is critical for viscous chemical fluids, as lower pressure drops mean less energy consumption.

Trends & Market Insights

The global market for Electric Ball Valves in the chemical industry is projected to grow at a CAGR of 7.2% from 2024 to 2030, reaching £2.1 billion, according to a report by Grand View Research. Key drivers include:

- Automation Adoption: 85% of new chemical plants in Europe are integrating fully automated valve systems, with Electric Ball Valves as the top choice.

- Sustainability Demands: Energy-efficient Valves help plants meet net-zero targets by reducing energy use and waste from leaks.

- Smart Technology: IoT-enabled Ball Valves with predictive maintenance features are gaining traction—these valves alert operators to potential issues before they cause failures.

Style & Usage Recommendations

When selecting Ball Valves for chemical applications, follow these guidelines to maximize performance:

- Match Valve Size to Pipeline Needs: Oversized valves waste energy, while undersized ones cause pressure issues. Use the ISO 5167 standard to calculate the required flow capacity.

- Check Certification: For hazardous chemicals, choose ATEX or IECEx-certified Electric Ball Valves to ensure explosion safety. For food-grade chemicals, opt for FDA-approved seals.

- Integrate with Existing Systems: Ensure the valve’s control protocol (e.g., Modbus, Profinet) is compatible with your plant’s SCADA system to avoid integration headaches.

- Schedule Regular Inspections: Even low-maintenance Electric Valves benefit from quarterly visual checks—look for signs of corrosion or seal wear.

Conclusion

Electric Ball Valves are no longer a “nice-to-have” in the chemical industry—they’re a strategic investment in safety, efficiency, and compliance. By solving core pain points like corrosion, imprecision, and high maintenance, these valves deliver tangible cost savings and operational peace of mind.

FAQ

Q1: Are Electric Ball Valves suitable for high-temperature chemical processes?

A1: Yes—look for models with high-temperature seals and heat-resistant motor casings. Many Electric Ball Valves handle temperatures up to 400°C, making them ideal for processes like distillation.

Q2: How do Electric Ball Valves compare to hydraulic valves in chemical plants?

A2: They are more energy-efficient and easier to maintain. Hydraulic valves are better for extremely high-pressure applications, but 90% of chemical processes don’t need this capacity.

Q3: Can Electric Ball Valves be used with toxic chemicals?

A3: Absolutely. Choose double-sealed Electric Ball Valves with leak detection sensors. These valves meet strict safety standards for toxic fluid handling, preventing environmental contamination.

Q4: What is the typical installation time for Electric Ball Valves?

A4: For a standard pipeline, installation takes 1–2 hours per valve—faster than pneumatic valves. Our team offers turnkey installation services to minimize downtime.

Q5: Do Electric Ball Valves require a backup power source?

A5: It’s recommended for critical processes. Most smart Ball Valves have battery backups that kick in during power outages, keeping valves in a safe position until power is restored.

Q6: How often do Electric Ball Valves need to be calibrated?

A6: Smart models self-calibrate, so manual calibration is only needed every 12–18 months. Traditional electric valves require calibration every 6–9 months.