Quick Overview

In fluid systems, backflow is not just inconvenient—it can be dangerous. Two common devices used to prevent it are vacuum breakers and check valves. While they often appear to serve the same purpose, their working principles, applications, and limitations are very different. At Vcore Valve, we regularly help customers choose between these two solutions based on real-world operating conditions. This guide breaks it all down clearly and practically.

A Real-World Scenario: Where Confusion Begins

Imagine this: a facility engineer notices water contamination in a downstream process line. The system already has a check valve installed, yet the issue persists. A plumber suggests adding a vacuum breaker instead.

So which one is actually needed? And why didn’t the check valve solve the problem?

This is a conversation we have almost weekly with buyers and engineers.

User Pain Points

1. Misunderstanding Backflow Protection

Many users assume all backflow prevention devices work the same way. In reality, vacuum breakers and check valves address different backflow mechanisms.

2. Wrong Valve, Wrong Application

Installing a check valve where negative pressure exists—or a vacuum breaker in a pressurised line—often leads to system failure.

3. Compliance and Safety Risks

Incorrect valve selection can violate plumbing codes or industrial safety standards, especially in potable water systems.

Practical Solutions and Expert Advice

1. Identify the Type of Backflow Risk

Is the risk caused by backpressure or backsiphonage?

-

Backpressure → Check valve

-

Backsiphonage → Vacuum breaker

2. Match the Valve to Operating Conditions

Consider pressure range, temperature, installation orientation, and fluid type before selecting a valve.

3. Follow Industry Standards

Local plumbing codes and industrial regulations often specify when a vacuum breaker vs check valve must be used.

Case Examples from the Field

Case 1: Commercial Plumbing System

A commercial building experienced contaminated water during sudden supply interruptions. The system had a check valve but no vacuum breaker. Once a vacuum breaker was installed at critical points, the issue disappeared.

Case 2: Industrial Cooling Line

An industrial cooling circuit used a vacuum breaker where continuous pressure existed. Replacing it with a spring-loaded check valve improved reliability and reduced maintenance downtime.

Technical Comparison: Vacuum Breaker vs Check Valve

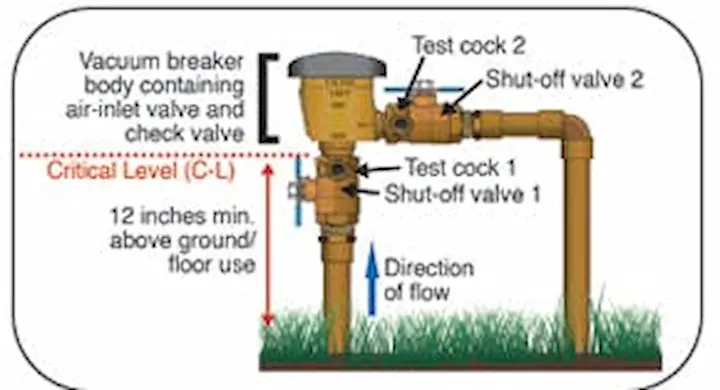

How a Vacuum Breaker Works

A vacuum breaker allows air into the system when negative pressure occurs. This breaks the vacuum and prevents contaminated water from being siphoned backwards.

Key characteristics:

-

Operates under atmospheric pressure

-

Prevents backsiphonage only

-

Not suitable for constant pressure

How a Check Valve Works

A check valve (also known as a non-return valve) allows flow in one direction and automatically closes when flow reverses.

Key characteristics:

-

Works under pressure

-

Prevents backpressure

-

Suitable for continuous operation

Side-by-Side Comparison

| Feature | Vacuum Breaker | Check Valve |

|---|---|---|

| Prevents backsiphonage | Yes | Limited |

| Prevents backpressure | No | Yes |

| Works under constant pressure | No | Yes |

| Common applications | Plumbing, irrigation | Industrial, HVAC, pipelines |

Market Trends and Industry Insights

Globally, stricter water safety regulations are increasing demand for backflow prevention solutions. In residential and commercial plumbing, vacuum breakers are becoming mandatory in many regions. Meanwhile, industrial sectors continue to rely heavily on advanced check valve designs with low cracking pressure and improved sealing.

At Vcore Valve, we are seeing strong growth in demand for stainless steel and brass check valves designed for higher efficiency and longer service life.

Usage Tips and Selection Guidance

-

Use a vacuum breaker for hose bibs, irrigation systems, and potable water lines exposed to siphoning risk.

-

Use a check valve in pump discharge lines, industrial pipelines, and pressurised systems.

-

Never rely on one device to replace the other—they are complementary, not interchangeable.

When in doubt, consult valve specialists who understand both standards and real operating conditions.

Conclusion

Choosing between a vacuum breaker vs check valve is not about which is better—it’s about which is correct for your system. Each valve plays a distinct role in protecting water quality, equipment, and safety. At Vcore Valve, we design and supply valves based on practical engineering logic, not guesswork. Selecting the right valve today prevents costly failures tomorrow.

If you’re unsure which solution fits your application, our technical team is always ready to help.

FAQ

What is the main difference between a vacuum breaker and a check valve?

A vacuum breaker prevents backsiphonage by introducing air, while a check valve prevents reverse flow caused by backpressure.

Can a check valve replace a vacuum breaker?

No. A check valve cannot reliably prevent backsiphonage under negative pressure conditions.

Are vacuum breakers required by plumbing codes?

In many regions, yes—especially for potable water systems and irrigation lines.

Do check valves need regular maintenance?

Yes. Periodic inspection ensures proper sealing and prevents wear-related leakage.

Can both valves be used together?

Absolutely. In complex systems, using both provides comprehensive backflow protection.