Quick Summary

Knife gate valves are purpose-built for tough media such as slurry, pulp, powder and wastewater. Unlike conventional gate valves, their thin blade design allows them to cut through solids rather than fight against them. In this guide, Vcore Valve explains how knife gate valves work, where they perform best, where they fail, and how to select the right configuration for long-term reliability.

A Common Scene on Site

An engineer tightens the handwheel, expecting isolation. Instead, the valve jams halfway. The medium is thick, abrasive and unforgiving. This is where standard gate valves struggle—and where a properly selected knife gate valve earns its place.

The Real Pain Points Users Face

Clogging and blockage

Traditional valves trap solids inside the body cavity, causing incomplete closure or seizure.

Rapid wear in abrasive service

Slurry, tailings and fibrous media erode seats and gates far faster than clean liquids.

Leakage after short service life

Incorrect sealing design leads to bypass leakage, even when the valve appears fully closed.

Practical Solutions That Actually Work

Use a true knife-edge gate

A sharpened blade cuts through solids instead of compressing them.

Choose sealing based on media, not price

Soft seals for tight shut-off, metal seats for abrasion—there is no universal option.

Match valve design to installation orientation

Vertical pipelines behave very differently from horizontal slurry lines.

What Exactly Is a Knife Gate Valves?

A knife gate valve is a linear-motion isolation valve designed with a thin, flat gate that slides into the flow path. Its geometry minimises flow obstruction and prevents material build-up, making it ideal for difficult media.

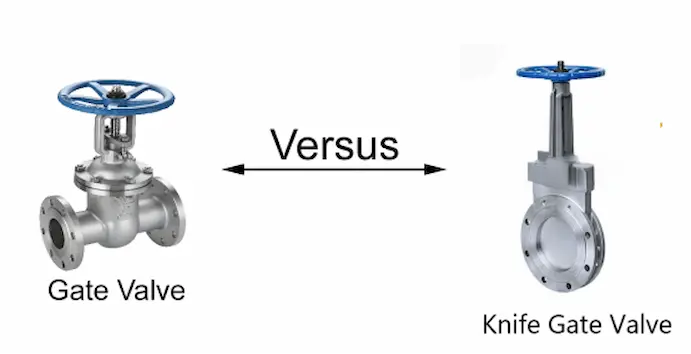

Compared with standard gate valves, knife gate valves prioritise cutting ability over pressure containment, which explains both their strengths and limitations.

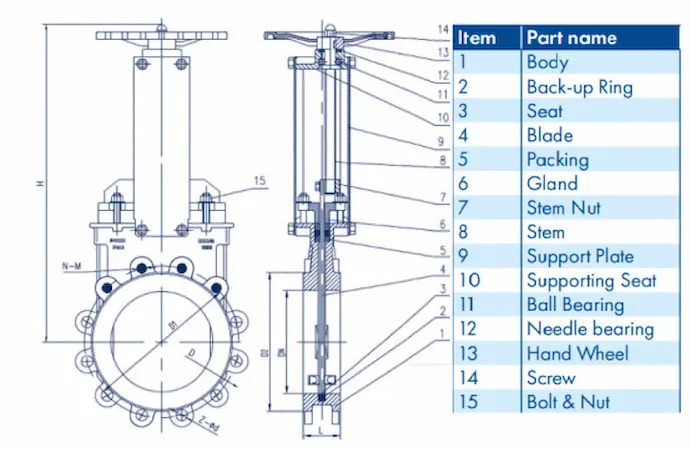

Knife Gate Valve Design Explained

Key Structural Features

-

Thin blade-style gate

-

Minimal body cavity

-

Full-port or near full-port opening

-

Top-entry packing system

Common Body Styles

-

Wafer knife gate valve

-

Lugged knife gate valve

-

Flanged knife gate valve

Each configuration affects installation flexibility, pressure rating and maintenance access.

Technical Comparison: Knife Gate Valve vs Traditional Gate Valve

| Parameter | Knife Gate Valve | Standard Gate Valve |

|---|---|---|

| Media suitability | Slurry, solids, pulp | Clean liquids, gases |

| Gate thickness | Thin blade | Thick wedge |

| Sealing method | Soft or metal seat | Metal-to-metal |

| Pressure capability | Low to medium | Medium to high |

| Clogging risk | Very low | High in slurry |

| Typical industries | Mining, wastewater | Oil, steam, water |

Real Application Examples

Mining slurry pipelines

Knife gate valves isolate abrasive tailings lines where ball or gate valves fail within months.

Pulp and paper plants

Fibrous media passes freely without wrapping around the gate.

Wastewater treatment

Ideal for sludge, grit and mixed solids in low-pressure systems.

Data-Driven Performance Insights

Field data from Vcore Valve installations shows:

-

Up to 60% longer service life in slurry lines compared to conventional gate valves

-

Lower operating torque due to reduced friction

-

Faster isolation in emergency shut-down scenarios

However, knife gate valves are not suitable for high-pressure or zero-leakage critical isolation without proper sealing selection.

Market Trends and Industry Direction

-

Increased use in renewable energy waste handling

-

Rising demand for actuated knife gate valves

-

Strong growth in mining and mineral processing projects

-

Greater focus on replaceable seat and gate designs to reduce lifecycle cost

Selection and Usage Tips from Vcore Valve

-

Always define media composition, not just “slurry”

-

Verify pressure and temperature limits early

-

Consider flush ports for sticky media

-

Do not overspecify—knife gate valves are functional tools, not decorative hardware

Conclusion: When Knife Gate Valves Make Sense

Knife gate valves are not universal solutions, but when applied correctly, they outperform almost every alternative in severe service conditions. At Vcore Valve, we design knife gate valves for real-world abuse, not laboratory theory.

If your system moves solids, fibres or slurry, choosing the right knife gate valve is not optional—it is essential.

FAQ

What is a knife gate valve mainly used for?

Knife gate valves are primarily used for isolating slurry, powder, pulp and other solids-laden media where conventional valves are prone to blockage.

Can knife gate valves handle high pressure?

Generally no. Most knife gate valves are designed for low to medium pressure applications. For high-pressure systems, alternative valve types should be considered.

What is the difference between a knife gate valve and a gate valve?

A knife gate valve uses a thin blade to cut through solids, while a gate valve uses a thick wedge designed for clean fluids and pressure containment.

Do knife gate valves provide bubble-tight shut-off?

Only when equipped with appropriate soft seals. Metal-seated designs prioritise durability over absolute tightness.

How often should knife gate valves be maintained?

Maintenance frequency depends on media abrasiveness, operating cycles and sealing design, but periodic inspection is strongly recommended.

Are knife gate valves suitable for automation?

Yes. Pneumatic and electric actuators are commonly used, especially in remote or hazardous environments.

Reference

-

API 600 – Steel Gate Valves: Design and Application

-

ASME B16.34 – Valves: Pressure and Temperature Ratings

-

ISO 10434 – Bolted Bonnet Steel Gate Valves

-

Valve Manufacturers Association (VMA) Handbook

-

Crane Co. Flow of Fluids Technical Paper TP-410

-

Union Valve Technical Knowledge Base

-

Vcore Valve Engineering Application Notes and Field Data