Product Introduction

Our Double Block and Bleed Valve (DBB)is a specialized industrial valve designed to provide two independent fluid isolation barriers and a vent/bleed port located between them. This architecture allows operators to isolate sections of a pipeline from both upstream and downstream fluid sources, then safely vent or bleed pressure trapped between the sealing surfaces before maintenance or inspection procedures.

Specifically defined by API 6D as a “single valve with two seating surfaces that, in the closed position, provides a seal against pressure from both ends with a means of venting/bleeding the cavity between the seating surfaces,” DBB valves are used where safe and verified isolation is critical to system integrity and personnel safety.

Why Double Block and Bleed Matters

Traditional isolation methods often rely on multiple individual valves — two isolation valves plus a separate vent valve. This setup introduces additional leak points, greater space requirements, and longer installation times. Our DBB valve consolidates these functions into a single compact package, leading to significant advantages in safety and efficiency:

-

Enhanced Safety: Dual isolation with a bleed port offers an extra layer of protection against unintended flow, essential when working with hazardous or high-pressure fluids.

-

Reduced Space & Weight: One DBB valve replaces multiple conventional valves and fittings, optimizing plant layout and reducing structural load.

-

Simplified Maintenance: The integrated bleed port allows trapped pressure to be released before disassembly, protecting both workers and equipment.

-

Lower Leak Paths: With fewer joints and connections, the potential for leakage — and subsequent environmental or safety issues — is dramatically reduced.

How It Works: Dual Isolation + Bleeding Mechanism

Our DBB valve typically consists of two block sealing surfaces stacked in series, with a vent/bleed valve located between them. In normal operation, both block seats remain open to allow fluid flow. When isolation is required:

-

The upstream block seat closes to stop flow from the supply side.

-

The downstream block seat closes to contain fluid pressure from the other side.

-

The bleed valve opens to safely relieve pressure and drain the cavity between the block seats, ensuring a zero-pressure environment before maintenance.

This sequence provides secure verification that the system is isolated and safe, especially essential for conditions such as hot work, confined space entry, or downstream maintenance.

Key Features & Technical Benefits

Dual Sealing Isolation

Two independent sealing surfaces provide robust barriers against upstream and downstream fluid pressures.

Integrated Bleed Port

Venting capability between seals ensures trapped media can be safely discharged, confirming pressure reduction before work begins.

API-Compliant Performance

Manufactured according to recognized standards including API 6D, EEMUA 182, BS6755 PT2, and others for verified reliability under critical service conditions.

Compact, Space-Saving Design

One DBB unit dramatically reduces installed footprint compared to traditional assemblies of multiple valves.

Wide Material & Connection Options

Available in carbon steel, stainless steel, duplex alloys, and fitted with flanged, threaded, or welded ends to suit diverse industrial environments.

Low Emission & High Integrity

Optional testing to low emission standards ensures minimal fugitive emissions and compliance with environmental requirements.

Typical Applications

DBB valves are employed in systems where isolation assurance and safety are paramount:

-

Oil & Gas Transmission & Storage: Preventing cross-flow and ensuring safe maintenance of high-pressure lines.

-

Petrochemical & Refinery Units: Isolating reactors, injectors, and instrument manifolds for safe servicing.

-

Chemical Processing: Handling aggressive or hazardous fluids with strict isolation and venting requirements.

-

Meter Calibration & Instrumentation: Ensuring leak-free conditions for precise measurement and testing.

-

Marine & Offshore Platforms: Compact valve design reduces space and improves safety in congested installations.

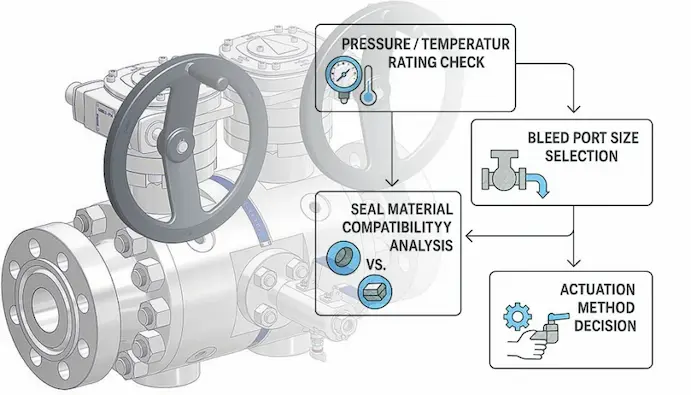

Material & Design Options

To meet specific project needs, Vcore Valve DBB valves are customizable with features such as:

-

Body Materials: Carbon steel, WCB, WC6, duplex steel, SS304/316, CF8/CF8M

-

Sealing Components: PTFE, PEEK, metal seats for high-temperature or abrasive service

-

Connection Types: Flanged (ANSI/DIN), butt weld, socket weld, threaded

-

Operation: Manual, gear-operated, pneumatic, electric actuator

-

Special Features: Injection quills, sampling ports, built-in check valves, seat wipers

These options ensure that your DBB valves are highly suited to the fluid media, pressure class, and operating environment of your system.

Technical Specifications

| Parameter | Details |

|---|---|

| Valve Type | Double Block and Bleed Valve (DBB) |

| Size Range | 1″ – 24″ (DN25 – DN600) |

| Pressure Class | 150 – 2500 lbs |

| Standards | API 6D, EEMUA 182, BS6755 PT2 |

| Materials | Carbon Steel, Stainless Steel, Duplex |

| Connection | Flanged, Welded, Threaded |

| Operation | Manual, Gear, Pneumatic, Electric |

| Media | Gas, Liquid, Chemical, High-Temp Service |

Why Choose Vcore Valve DBB Valves

At Vcore Valve, we design our double block and bleed valves from the ground up with safety, reliability, and operational efficiency as the top priorities. Every valve is precision-machined, thoroughly tested, and engineered to minimize leakage paths, reduce installation time, and ensure a safe maintenance environment. Our DBB solutions combine space-saving design with performance integrity, backed by rigorous quality control and international compliance.

Whether your project involves energy infrastructure, petrochemical processing, or industrial fluid control, Vcore Valve DBB valves deliver peace of mind with proven sealing performance and safe pressure management.

FAQs

1. What is a Double Block and Bleed Valve?

A Double Block and Bleed Valve (DBB) is a type of valve that consists of two independent sealing points and a bleed valve in between. This design allows for the safe isolation of a pipeline or system section, while the bleed valve enables any accumulated pressure or fluid to be safely vented.

2. What are the primary applications of DBB valves?

DBB valves are commonly used in applications that require the isolation of hazardous or pressurized fluids, particularly in oil and gas, chemical processing, and refining industries. They are also employed where safety and leak prevention are critical, such as in pipelines, valves, and critical equipment where maintenance or isolation is required.

3. Why is a Double Block and Bleed Valve important in safety applications?

The DBB valve provides an extra layer of security by offering two independent barriers to fluid flow, significantly reducing the risk of leaks or spills. The bleed valve ensures that any trapped pressure can be safely vented, further enhancing safety during maintenance or repair activities.

4. How does the Double Block and Bleed Valve differ from a single block valve?

Unlike a single block valve, which has one isolation point, the Double Block and Bleed Valve features two seals with a bleed valve between them. This design ensures that, even if one seal fails, the second seal provides an additional safety measure, making it more reliable for critical applications where fluid isolation is paramount.

5. What is the typical pressure rating for DBB valves?

The pressure rating for DBB valves varies based on the specific product and material specifications. They are typically available in pressure classes ranging from 150 to 2500 psi, with each valve being designed to withstand specific conditions depending on the application.