Quick Summary

Discussing floating vs fixed ball valves is a critical topic in pipeline system design. Although both are quarter-turn ball valves, their internal structures, pressure-handling capabilities and application suitability differ significantly. At Vcore Valve, we help engineers make informed decisions by matching valve design with real operating conditions, not just catalogue data.

A Familiar Engineering Conversation

“Both are ball valves—so what’s the real difference?”

“Pressure, torque, reliability… and whether it survives five years or five months.”

This question often arises during project bidding or plant retrofits. Understanding the structural logic behind floating and fixed ball valves prevents costly mistakes.

Common User Pain Points

Incorrect Valve Selection

Many projects choose floating ball valves for high-pressure lines where fixed ball valves are more appropriate.

Excessive Operating Torque

Improper selection leads to oversized actuators and unstable automation performance.

Unexpected Leakage and Wear

Seat deformation and uneven load distribution shorten valve service life.

Practical Solutions and Selection Principles

Match Valve Type to Pressure Class

Floating ball valves suit low to medium pressure; fixed ball valves excel in high-pressure systems.

Consider Pipeline Size

Large diameter pipelines benefit from the structural stability of fixed ball valves.

Plan for Long-Term Operation

Lower operating torque and balanced load distribution significantly reduce maintenance frequency.

What Is a Floating Ball Valve?

A floating ball valve features a ball that is not mechanically fixed in position. Under line pressure, the ball moves slightly downstream, pressing against the seat to achieve sealing.

Key Characteristics

-

Simple internal structure

-

Sealing relies on media pressure

-

Lower manufacturing cost

-

Suitable for small to medium sizes

-

Common in water, gas and general industry

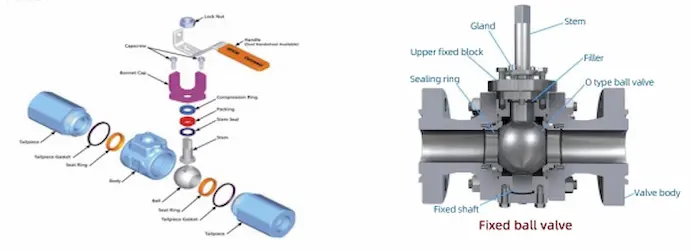

What Is a Fixed Ball Valve?

A fixed ball valve, also known as a trunnion-mounted ball valve, uses upper and lower trunnions to hold the ball firmly in place. Sealing is achieved by spring-loaded seats moving towards the ball.

Key Characteristics

-

Ball remains stationary

-

Seats move to form a seal

-

Handles higher pressure

-

Lower operating torque

-

Ideal for large diameter pipelines

Structural Comparison: Floating vs Fixed Ball Valves

| Feature | Floating Ball Valve | Fixed Ball Valve |

|---|---|---|

| Ball support | Free floating | Trunnion supported |

| Sealing mechanism | Ball moves to seat | Seat moves to ball |

| Pressure handling | Low–medium | Medium–high |

| Valve size range | Small–medium | Medium–large |

| Operating torque | Higher under pressure | Lower and stable |

| Cost | Lower | Higher |

Case Study: High-Pressure Gas Pipeline

A gas transmission project initially specified floating ball valves for DN400 pipelines. After torque calculations and safety analysis, Vcore Valve recommended fixed ball valves.

Results:

-

Actuator size reduced by 30%

-

Improved sealing stability

-

No seat deformation after long-term testing

Data-Based Performance Comparison

Engineering data and field feedback show:

-

Fixed ball valves reduce torque by up to 40% under high pressure

-

Floating ball valves experience increased seat stress as pressure rises

-

Trunnion-mounted designs distribute load more evenly across seats

This explains why fixed ball valves dominate oil & gas and high-pressure process systems.

Market Trends and Industry Insight

Industry trends indicate:

-

Rising demand for fixed ball valves in LNG, oil & gas, and power generation

-

Continued popularity of floating ball valves in water and general industrial services

-

Increasing focus on lifecycle cost rather than initial purchase price

At Vcore Valve, most large-diameter projects now specify fixed ball valves by default.

Style and Usage Recommendations

Choose a floating ball valve when:

-

Pipeline pressure is moderate

-

Size is relatively small

-

Cost efficiency is a priority

Choose a fixed ball valve when:

-

Pressure is high

-

Diameter exceeds DN200

-

Automation and torque stability matter

Conclusion

Both floating and fixed ball valves have their place. The key lies in understanding how structural design affects performance under real conditions.

At Vcore Valve, we don’t sell “one-size-fits-all” solutions—we engineer valves that fit your system.

👉 Contact Vcore Valve for technical selection support or customised ball valve solutions.

FAQs

Q1: What is the main difference between floating and fixed ball valves?

The ball movement and sealing mechanism differ significantly.

Q2: Which valve is better for high pressure?

Fixed ball valves are more suitable for high-pressure applications.

Q3: Are floating ball valves cheaper?

Yes, due to a simpler structure and lower material cost.

Q4: Can fixed ball valves be automated easily?

Yes, their lower torque makes automation more reliable.

Q5: Which valve has a longer service life?

Fixed ball valves generally offer longer service life in demanding conditions.

Q6: Does pipeline size affect valve choice?

Absolutely—larger pipelines benefit from fixed ball valve designs.