Quick Overview

gate valve vs butterfly valve is a common compare in pipeline design and industrial projects. While both are used to control fluid flow, their structure, performance, and ideal applications differ significantly. In this guide, Vcore Valve breaks down their functions, advantages, limitations, and real-world uses—helping you select the right valve with confidence.

Opening Scenario: A Familiar Engineering Debate

“Should we install a gate valve for full bore flow, or go with a butterfly valve to save space and cost?”

This question comes up repeatedly on construction sites and in engineering offices. The answer depends not on preference, but on how each valve truly functions in service.

User Pain Points

Pain Point 1: Misunderstanding Valve Functions

Many users believe gate and butterfly valves perform the same role—this often leads to poor valve selection.

Pain Point 2: Space and Installation Constraints

Limited installation space can rule out certain valve types.

Pain Point 3: Long-Term Maintenance Costs

Choosing the wrong valve can increase downtime and maintenance expenses.

Solutions & Practical Recommendations

Solution 1: Match Valve Function to Application

Gate valves and butterfly valves serve different operational purposes.

Solution 2: Consider Installation Environment Early

Space, weight, and actuation method matter more than expected.

Solution 3: Work with Experienced Manufacturers

At Vcore Valve, selection advice is based on real operating conditions, not catalog descriptions.

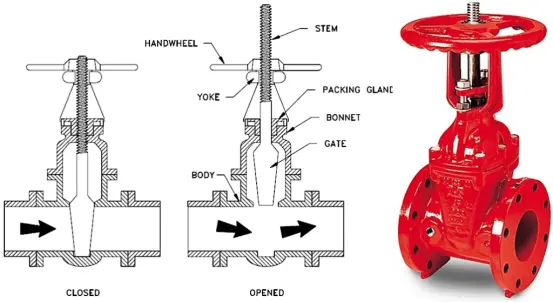

What Is a Gate Valve?

A gate valve controls flow by raising or lowering a flat or wedge-shaped gate into the flow path. It is designed primarily for on/off service, not throttling.

Key Functions of Gate Valves:

-

Full bore, unobstructed flow

-

Minimal pressure drop when fully open

-

Reliable shut-off in large-diameter pipelines

Typical Applications:

-

Oil and gas pipelines

-

Water transmission lines

-

Power generation systems

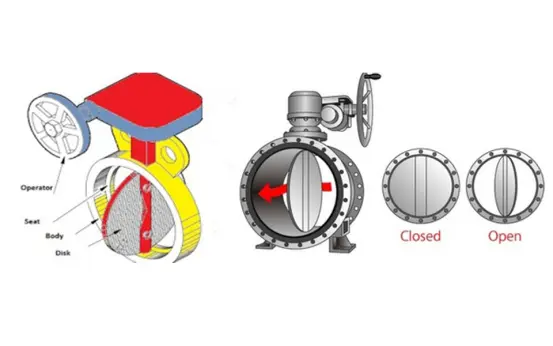

What Is a Butterfly Valve?

A butterfly valve uses a rotating disc mounted on a shaft to regulate flow. A quarter-turn movement opens or closes the valve.

Key Functions of Butterfly Valves:

-

Fast operation

-

Compact and lightweight design

-

Suitable for throttling and isolation

Typical Applications:

-

HVAC systems

-

Water treatment plants

-

Chemical and industrial process lines

Gate Valve vs Butterfly Valve: Technical Comparison

| Feature | Gate Valve | Butterfly Valve |

|---|---|---|

| Operation | Linear (multi-turn) | Quarter-turn |

| Flow Control | On/Off only | On/Off & throttling |

| Pressure Drop | Very low | Moderate |

| Installation Space | Large | Compact |

| Weight | Heavy | Lightweight |

| Cost | Higher (large sizes) | More economical |

| Maintenance | More complex | Easier |

Case Studies & Real Applications

Case 1: Water Transmission Pipeline

A gate valve was selected for a long-distance water pipeline to ensure full bore flow and minimal pressure loss.

Case 2: Industrial Cooling System

A butterfly valve reduced installation space and improved operational efficiency with fast actuation.

Data, Performance & Engineering Analysis

From a fluid dynamics perspective, gate valves provide near-zero flow resistance when fully open. However, their slow operation and large size limit their suitability in modern compact systems.

Butterfly valves, while introducing slight turbulence, offer faster control and lower installation costs—especially in large diameters.

Market Trends & Industry Insights

-

Increasing preference for butterfly valves in HVAC and water treatment

-

Gate valves remain dominant in high-pressure and critical isolation services

-

Automation trends favour quarter-turn valves for actuation compatibility

Manufacturers are also improving sealing technologies to expand butterfly valve pressure ratings.

Style & Usage Recommendations

Choose a gate valve if:

-

Full-bore flow is critical

-

The valve is rarely operated

-

High-pressure isolation is required

Choose a butterfly valve if:

-

Space and weight are limited

-

Frequent operation is expected

-

Cost efficiency is important

Conclusion

Gate valves and butterfly valves are not interchangeable—they are tools designed for different jobs. Selecting the right one improves system efficiency, safety, and service life.

👉 Contact Vcore Valve today to get expert advice on selecting the ideal valve for your application.

FAQs

Q1: What is the main difference between gate and butterfly valves?

Gate valves use linear motion for isolation, while butterfly valves use quarter-turn rotation.

Q2: Can a gate valve be used for throttling?

No, gate valves are not designed for flow regulation.

Q3: Are butterfly valves suitable for large diameters?

Yes, butterfly valves are often preferred for large pipelines due to lower weight and cost.

Q4: Which valve is easier to automate?

Butterfly valves are easier to automate due to quarter-turn operation.

Q5: Which valve requires more maintenance?

Gate valves generally require more maintenance over time.