Quick Summary

Choosing between globe valves and gate valves is not just a matter of preference—it directly affects flow control accuracy, pressure loss, service life, and system safety. At Vcore Valve, we often see costly mistakes caused by selecting the wrong valve type. This guide clearly explains the structural, functional, and application differences to help you make the right decision the first time.

A Real-World Scenario: Which Valve Should You Choose?

Imagine this:

Your engineer specifies a gate valve for a steam line that requires throttling. Six months later, vibration, seat erosion, and leakage appear. The valve wasn’t faulty—the selection was.

This exact scenario is why understanding globe valves vs gate valves matters far more than most buyers realise.

Common User Pain Points

Unclear functional differences

Many buyers assume all shut-off valves perform similarly, overlooking how internal design impacts performance.

Wrong valve used for flow regulation

Gate valves are often misused for throttling, leading to rapid wear and unstable control.

Unexpected pressure drop or leakage

Incorrect valve choice can cause unnecessary energy loss and maintenance issues.

Practical Solutions from Vcore Valve

Use globe valves for precise control

If your system requires throttling or frequent adjustment, a globe valve is designed specifically for this purpose.

Choose gate valves for full open or full close service

For minimal pressure loss and straight-through flow, gate valves are the better option.

Match valve type to operating conditions

Consider pressure, temperature, media, and operation frequency—not just price.

Case Study Examples

Case 1: Steam Distribution System

A chemical plant replaced gate valves with globe valves on steam branches requiring modulation. Result: 30% reduction in maintenance frequency and improved temperature stability.

Case 2: Water Transmission Pipeline

Gate valves were retained for isolation points, reducing pressure loss and improving pump efficiency over long distances.

Technical Comparison and Performance Data

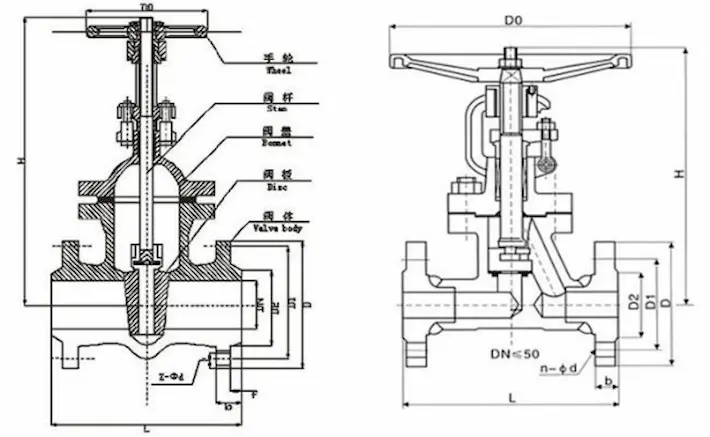

| Feature | Globe Valve | Gate Valve |

|---|---|---|

| Flow Control | Excellent | Poor |

| Pressure Drop | Higher | Very low |

| Sealing Performance | Strong under throttling | Best in fully open/close |

| Operation Frequency | Suitable for frequent use | Best for occasional use |

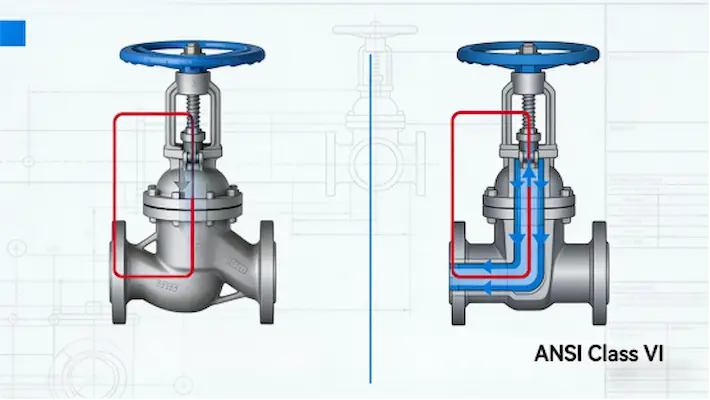

| Flow Path | Zigzag | Straight-through |

The internal flow path explains why globe valves offer better control but higher pressure loss, while gate valves excel in isolation applications.

Industry Trends and Market Insights

-

Increasing automation is driving demand for globe valves in control systems

-

Energy efficiency regulations favour low-pressure-loss gate valves in pipelines

-

Steam and thermal systems increasingly specify globe valves for safety compliance

Manufacturers now focus on optimising materials and seat designs to extend service life in harsh environments.

Selection and Usage Recommendations

-

Use globe valves for steam, fuel oil, and process control lines

-

Use gate valves for water supply, fire protection, and main isolation points

-

Avoid throttling with gate valves

-

Always consider actuator compatibility and maintenance access

At Vcore Valve, we support customised selection based on real operating data—not assumptions.

Conclusion and Call to Action

Understanding the true differences between globe valves and gate valves helps you avoid performance issues, reduce downtime, and improve system reliability. The right valve is not the cheapest one—it’s the one that matches your application.

👉 Contact Vcore Valve today for expert valve selection support, OEM solutions, and long-term reliability you can trust.

FAQ

Q1: Can a gate valve be used for flow control?

Gate valves are not recommended for throttling, as partial opening causes vibration and seat damage.

Q2: Why do globe valves have a higher pressure drop?

The internal flow path changes direction, which improves control accuracy but increases resistance.

Q3: Which valve is better for steam systems?

Globe valves are generally preferred due to their precise control and stable sealing.

Q4: Are gate valves more durable than globe valves?

Gate valves last longer in fully open or fully closed positions but wear quickly if misused.

Q5: How do I choose the correct valve size?

Selection should be based on flow rate, pressure class, temperature, and operating conditions.