Quick Overview

Our nozzle check valve, also known as a non slam check valve or axial flow check valve, is designed to prevent reverse flow while eliminating water hammer in pipelines. Unlike traditional swing or lift check valves, nozzle check valves use a spring-assisted axial disc that closes instantly and smoothly. This makes them ideal for high-velocity, high-pressure, and automated systems. At Vcore Valve, nozzle check valves are engineered for reliability, safety, and long-term performance in demanding industrial applications.

Opening Scenario: A Familiar Engineering Conversation

“The pump is fine, but every shutdown sounds like a hammer strike.”

“That’s not the pump—it’s your check valve.”

In many systems, replacing a conventional check valve with a nozzle check valve instantly solves noise, vibration, and pressure surge issues.

User Pain Points

Water Hammer and Pressure Surges

Traditional check valves close too slowly, causing damaging pressure spikes.

Excessive Noise and Vibration

Swing-type designs often slam shut, creating noise and mechanical stress.

High Maintenance and Short Service Life

Repeated impacts wear out seats, hinges, and sealing surfaces.

Solutions and Engineering Recommendations

Adopt Axial Flow Design

A non slam check valve closes in line with the flow, minimising turbulence.

Use Spring-Assisted Closure

Spring-loaded discs ensure fast, controlled closure before flow reversal occurs.

Match Valve Design to Flow Conditions

Correct sizing and spring selection optimise performance and longevity.

What Is a Nozzle Check Valve?

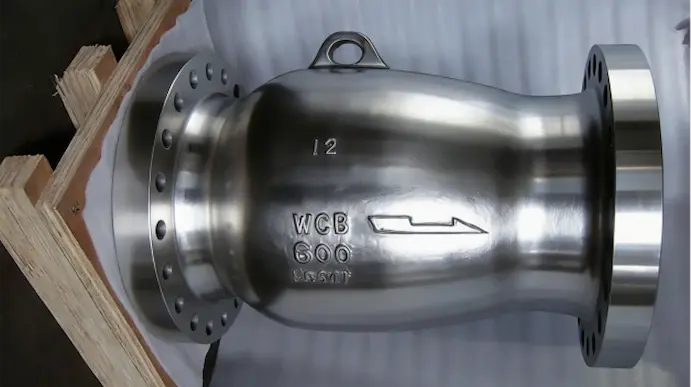

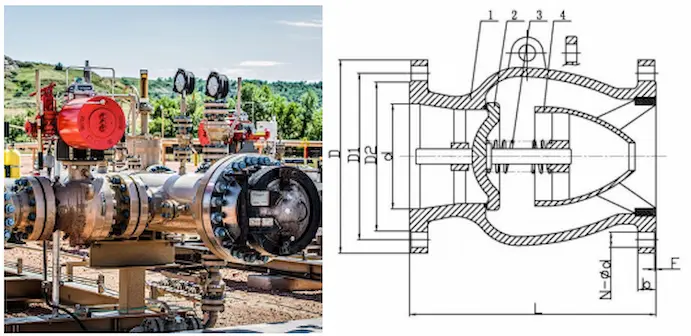

Our nozzle check valve is an inline check valve where the disc moves axially rather than swinging or lifting vertically. The disc is guided within a nozzle-shaped body and assisted by a calibrated spring.

Key Components

-

Streamlined valve body

-

Axial-flow disc or piston

-

Precision spring

-

Metal or soft sealing system

This design ensures smooth flow and instant closure without slamming.

How Nozzle Check Valves Work

During forward flow, fluid pressure compresses the spring and pushes the disc open. As flow decreases, the spring begins closing the disc before reverse flow occurs, preventing water hammer entirely.

This proactive closure is the core advantage over conventional designs.

Nozzle Check Valve vs Traditional Check Valves

| Feature | Nozzle Check Valve | Swing Check Valve | Lift Check Valve |

|---|---|---|---|

| Water hammer prevention | Excellent | Poor | Moderate |

| Noise level | Very low | High | Medium |

| Flow efficiency | High | Medium | Medium |

| Installation orientation | Any | Limited | Limited |

| Maintenance | Low | High | High |

Case Studies and Application Examples

Case 1: Power Plant Cooling System

A high-velocity cooling line experienced severe water hammer.

Solution:

Installed axial flow check valves downstream of pumps.

Result:

-

Eliminated pressure surges

-

Reduced pipeline stress

-

Extended pump and valve life

Case 2: Oil & Gas Pipeline

Frequent maintenance due to swing valve wear.

Solution:

Replaced with forged steel non-slam check valves.

Result:

-

Zero slam incidents

-

Lower lifecycle cost

-

Improved operational safety

Data, Fluid Dynamics, and Performance Analysis

Studies show nozzle check valves can reduce pressure surge intensity by up to 90% compared to swing check valves. Their streamlined internal geometry also delivers:

-

Lower pressure drop

-

Higher Cv values

-

Improved energy efficiency

For high-flow systems, this translates directly into reduced operating costs.

Market Trends and Industry Insights

-

Increasing adoption in power generation and desalination plants

-

Strong demand from oil & gas and petrochemical sectors

-

Preference for anti water hammer valves in automated pumping systems

-

Growing use of stainless steel and duplex materials

Nozzle check valves are becoming the default choice for critical flow control.

Style and Usage Recommendations

-

Install close to pumps for maximum protection

-

Choose forged steel bodies for high-pressure systems

-

Select stainless steel for corrosive or hygienic applications

-

Always size based on flow velocity, not pipe diameter alone

Correct selection ensures silent, reliable operation.

Conclusion

A nozzle check valve is not just a check valve—it is a protective device that safeguards pumps, pipelines, and entire systems. By eliminating water hammer, reducing noise, and lowering maintenance costs, it delivers measurable long-term value.

At Vcore Valve, we design and manufacture high performance nozzle check valves tailored to real industrial challenges.

👉 Contact Vcore Valve today to select the right non-slam solution for your system.

FAQs

What is a nozzle check valve used for?

It prevents reverse flow and eliminates water hammer in high-velocity systems.

Is a nozzle check valve better than a swing check valve?

Yes, especially for noise reduction, safety, and long-term reliability.

Can nozzle check valves be installed vertically?

Yes, they can be installed in any orientation.

Are nozzle check valves suitable for high pressure?

Absolutely, especially forged steel designs.

Do nozzle check valves require frequent maintenance?

No, their streamlined design significantly reduces wear.

Does Vcore Valve offer customised nozzle check valves?

Yes, materials, sizes, and spring settings can be customised.

References

-

API 594 – Check Valve Standard

-

ASME B16.34 – Valve Design and Pressure Ratings

-

Valve Manufacturers Association (VMA) Technical Guides

-

Fluid Transients in Pipeline Systems – ISA Publications

-

ISO 9001 Valve Manufacturing Guidelines