Quick Overview

Plug valves and gate valves are two of the most widely used industrial shut-off valves—but their structure, function and ideal applications differ greatly. At Vcore Valve, we often help buyers understand which one suits pipelines for water, oil, gas, chemical media or abrasive fluids. This guide compares plug valves and gate valves in design, performance, sealing, maintenance and best-use scenarios—allowing engineers and procurement teams to select confidently and avoid costly mismatches.

Opening Scenario

“Should we use a plug valve or a gate valve for this line?”

A question raised in nearly every project meeting.

The two valves may look simple, but mis-selection often leads to leakage, sticking, unbalanced torque, or hard-to-operate pipelines. Let’s break down the differences—without the usual jargon overload.

User Pain Points

Confusion About Valve Mechanisms

Many buyers cannot clearly distinguish the quarter-turn plug valve from the linear-motion gate valve, leading to incorrect assumptions about performance.

Poorly Matched Applications

Gate valves are often used for media they aren’t designed for, resulting in high torque, slow operation or premature sealing wear.

Maintenance Difficulties

Improper valve choice may require frequent lubrication, repacking or seal replacement, raising long-term maintenance cost.

Solutions & Expert Recommendations

Understand the Motion Type

Plug valves = quarter-turn, quick shut-off

Gate valves = linear rising/descending, slower shut-off

Selecting based on motion type dramatically reduces operator fatigue and improves reliability.

Match Media to Valve Type

Use plug valves for viscous, dirty, or slightly abrasive media.

Use gate valves for clean-water, gas, or low-viscosity fluids requiring full flow.

Prioritise Maintenance Access

Plug valves offer simple internal access and easy lubrication.

Gate valves require bonnet removal but provide long service life for clean media.

Main Differences Between Plug Valves and Gate Valves

Plug Valve Overview

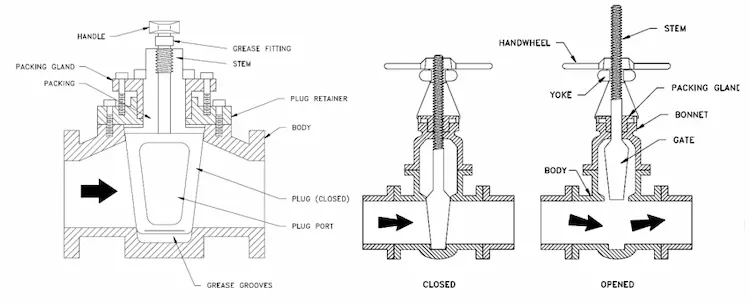

A plug valve uses a cylindrical or tapered plug that rotates 90 degrees to open or close flow. It is compact, fast-operating, and ideal for isolation and directional flow.

Key Features

-

Quarter-turn operation

-

Excellent shut-off capability

-

Suitable for slurries, gases, slightly dirty fluids

-

Available in lubricated or non-lubricated designs

Common Uses

Oil & gas pipelines, chemical distribution, compressed air, wastewater.

Gate Valve Overview

A gate valve uses a metal gate that moves up and down to permit or block flow. It is preferred where full-bore flow and minimal pressure drop are required.

Key Features

-

Linear rising or non-rising stem

-

Minimal flow resistance when fully open

-

Not ideal for throttling

-

Larger installation footprint

Common Uses

Water supply networks, irrigation, clean industrial pipelines.

Data & Technical Comparison

| Feature | Plug Valve | Gate Valve |

|---|---|---|

| Operation Type | Quarter-turn | Linear rising/descending |

| Flow Control | On/Off, limited throttling | On/Off only |

| Pressure Drop | Low | Very low when fully open |

| Seal Type | Tapered plug, elastomers | Metal–metal or soft seal |

| Media Compatibility | Gas, oil, slurry, viscous fluids | Clean water, steam, gas |

| Maintenance | Simple lubrication | Bonnet removal required |

| Cost | Moderate | Moderate–high |

Case Studies from Vcore Valve

Case 1 – Chemical Transfer Line

A customer previously used gate valves on viscous chemical lines, resulting in high torque and seat wear.

After switching to Vcore Valve plug valves, operation torque decreased by 45% and leak incidents dropped dramatically.

Case 2 – Municipal Water Supply

A water utility replaced plug valves with gate valves to achieve unobstructed full-flow capacity.

This change improved service pressure stability and reduced operational energy consumption.

Market Trends & Industry Insights

-

Increased demand for quarter-turn valves due to automation compatibility

-

Wider adoption of PTFE and elastomer-seated plug valves

-

Growing preference for lead-free and DZR materials

-

Expansion of plug valves in mid-pressure gas systems

Usage & Selection Tips

-

Choose plug valves for quick shut-off and dirty/viscous media

-

Choose gate valves for clean fluids and full-port applications

-

Avoid throttling with gate valves

-

Consider lubrication frequency when selecting plug valves

-

Always verify pressure class, temperature rating and material compatibility

Conclusion

Plug valves and gate valves each play essential roles in industrial flow control. Understanding their differences ensures the right valve is selected for safety, efficiency and long-term durability.

At Vcore Valve, we support engineers, distributors and OEM partners with expert guidance and high-performance valve solutions tailored to real-world applications.

👉 Contact Vcore Valve for drawings or customised valve solutions.

FAQ

Q1: What is the main difference between a plug valve and a gate valve?

A: A plug valve operates with a quarter-turn motion using a cylindrical plug, while a gate valve uses a linear rising gate to open or close flow.

Q2: Which valve is better for viscous or dirty fluids?

A: Plug valves perform better with viscous, dirty or slightly abrasive media due to their simple passageway and sealing design.

Q3: Are gate valves suitable for throttling?

A: No. Gate valves should not be used for throttling because partial opening causes vibration and seat damage.

Q4: Which valve is easier to maintain?

A: Plug valves are generally easier to maintain because the plug can be accessed for lubrication without removing the bonnet.

Q5: Do plug valves provide bubble-tight sealing?

A: Yes, especially soft-seated plug valves designed for gas and low-pressure liquid applications.