Quick Overview

Backflow preventers and check valves are both crucial components in controlling water flow and preventing contamination in plumbing systems. However, they serve different purposes and function differently. In this guide, we will compare the two, highlight their uses, and help you choose the right one for your specific needs.

Opening Scenario

Imagine you’re in charge of a busy industrial facility, and water flow is critical to the operation of your equipment. One day, you notice a contamination risk in the water supply. How can you ensure that harmful substances don’t flow back into your clean water supply? This is where backflow preventers and check valves come into play. But how do you know which one to choose?

User Pain Points

Confusion between Backflow Preventers and Check Valves

Many people struggle to understand the difference between a backflow preventer and a check valve. Both devices are used to control water flow, but their functions and applications are distinct.

Risk of Water Contamination

If backflow occurs in a plumbing system, hazardous substances can contaminate clean water. This can pose significant health risks, especially in industrial and commercial systems.

Incorrect Valve Selection

Choosing the wrong valve for a particular application can result in costly repairs, ineffective water flow control, or even legal liabilities, especially in industries that require strict compliance with health and safety regulations.

Solutions & Expert Recommendations

Understand the Function of Each Valve

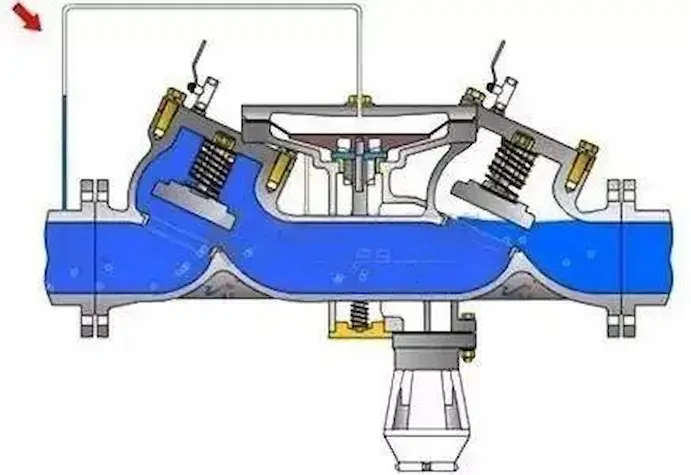

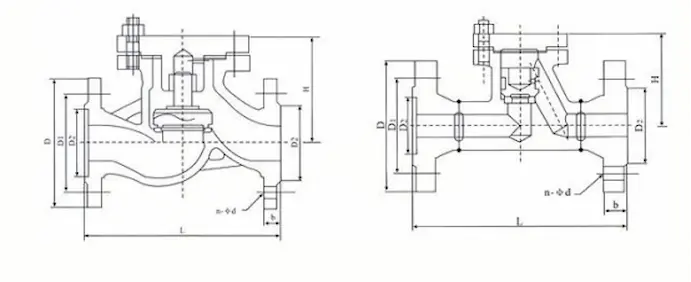

Backflow preventers are specifically designed to prevent water from flowing back into the clean water supply, often used in drinking water systems. On the other hand, check valves allow water to flow in one direction, preventing reverse flow but not actively blocking contamination.

Choose Based on System Needs

For systems where contamination is a concern, a backflow preventer is necessary. For standard water flow control where backflow isn’t a risk, a check valve may suffice.

Consider Compliance and Regulations

Ensure that the valve you choose complies with local water safety and plumbing regulations, especially in sensitive applications like healthcare, food production, or pharmaceuticals.

Case Studies from Vcore Valve

Case Study 1 – Industrial Water Supply

A manufacturing facility used a check valve in its water supply system. However, the system didn’t account for backflow risks from nearby chemical tanks. Installing a backflow preventer improved safety and complied with industry regulations, safeguarding the clean water supply from potential contamination.

Case Study 2 – Residential Plumbing

A homeowner replaced their traditional check valve with a backflow preventer in their irrigation system. This simple upgrade reduced the risk of contaminants entering their household water system after heavy rainfall.

Data & Technical Comparison

| Valve Type | Function | Application | Pressure Rating | Common Uses |

|---|---|---|---|---|

| Backflow Preventer | Prevents reverse flow | Drinking water systems | High | Residential, commercial |

| Check Valve | Allows flow in one direction | Industrial, plumbing | Medium | Water supply, fire systems |

Trends & Market Insights

-

Increasing Awareness of Water Safety

There is growing concern regarding water contamination and stricter regulations, especially in the food and beverage industry. This trend is pushing the demand for backflow preventers over traditional check valves. -

Rise of Smart Valves

Technological advancements are leading to the introduction of smart valves, including backflow preventers with automated shut-off features for enhanced safety. -

Environmental Concerns

Backflow preventers are increasingly seen as environmentally responsible solutions, as they protect public water supplies and prevent harmful chemicals from re-entering the ecosystem.

Usage & Selection Tips

-

For Residential Use:

Choose backflow preventers for irrigation systems or anywhere potable water could be contaminated. -

For Commercial and Industrial Use:

If backflow prevention is not a concern, check valves may be sufficient. However, if your system deals with chemicals or other hazardous substances, always opt for a backflow preventer. -

Check Valve for Simple Flow Control:

If you’re only controlling flow direction and there’s no risk of contamination, a check valve offers a simpler, more cost-effective solution.

Conclusion

Choosing between a backflow preventer and a check valve depends on your specific system requirements. Backflow preventers offer essential protection against water contamination, while check valves are suitable for controlling flow direction in non-contaminated systems. At Vcore Valve, we are experts in providing high-quality valves for all types of applications. Whether you need a backflow preventer for your drinking water system or a check valve for a more straightforward flow control solution, we have you covered.

👉 Contact Vcore Valve today for expert advice, valve selection, and a quote.

FAQ

Q1: What is the difference between a backflow preventer and a check valve?

A: A backflow preventer actively blocks water from flowing backward into the clean water supply, preventing contamination. A check valve only allows flow in one direction but does not specifically prevent backflow contamination.

Q2: When should I use a backflow preventer instead of a check valve?

A: Use a backflow preventer when contamination is a concern, such as in drinking water systems or areas with potential hazardous reverse flow. Use a check valve in systems where only flow direction matters.

Q3: Can a check valve prevent contamination?

A: No, a check valve prevents reverse flow but does not actively block contamination, unlike a backflow preventer.

Q4: Are backflow preventers required by law?

A: Yes, many jurisdictions require backflow preventers in certain applications, particularly in residential and commercial water systems, to comply with health and safety regulations.

Q5: How often should backflow preventers be inspected?

A: It’s recommended to inspect backflow preventers annually, especially in commercial or industrial systems where regulations are stricter.