Quick Overview

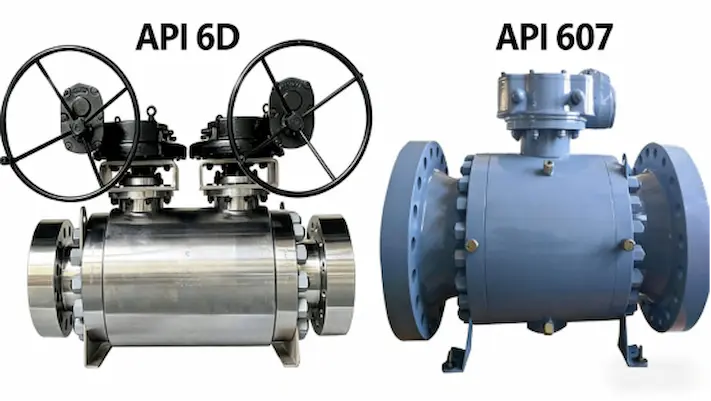

API 607 vs API 6D ball valves is a popular topic—even for experienced engineers. While both standards are widely used in oil, gas, and industrial applications, they serve very different purposes. At Vcore Valve, we often help clients clarify this distinction before costly specification mistakes occur.

A Real-World Engineering Scenario

“Is this valve API 607 or API 6D certified?”

It’s a question our sales engineers hear weekly.

One project manager assumes API 607 means “pipeline ready.” Another believes API 6D automatically guarantees fire safety. Both assumptions are wrong—and both can lead to rejected tenders or safety risks.

Common User Pain Points

Confusing standards terminology

API numbers are often mistaken for valve types rather than performance standards.

Incorrect tender specifications

Projects frequently request API 607 when API 6D is required—or vice versa.

Overpaying for unnecessary certification

Some systems demand fire testing; others don’t, yet clients specify it “just in case”.

Practical Solutions from Vcore Valve

Define the application first

Pipeline transmission? Process isolation? Fire-risk environment?

Match the standard to the risk, not the habit

Fire safety and pipeline integrity are not the same thing.

Choose a manufacturer experienced in both standards

At Vcore Valve, we manufacture API 607 fire-safe ball valves and API 6D pipeline ball valves, including customised solutions.

What Is API 607?

API 607 is a fire test standard for quarter-turn valves, including ball valves.

It verifies that a valve can maintain sealing integrity during and after fire exposure.

Key points:

-

Focuses on fire safety performance

-

Often aligned with ISO 10497

-

Applicable to soft-seated ball valves

-

Common in refineries, chemical plants, and fire-risk zones

At Vcore Valve, our API 607 ball valves undergo rigorous fire testing to ensure minimal leakage even after soft seat destruction.

From Union Tech

What Is API 6D?

API 6D is a product specification for pipeline valves used in oil and gas transmission.

Key points:

-

Covers design, materials, testing, and dimensions

-

Includes ball, gate, plug, and check valves

-

Mandatory for long-distance pipelines

-

Focuses on structural integrity and reliability

A valve can be API 6D compliant without being fire-tested, unless fire testing is additionally specified.

Technical Comparison: API 607 vs API 6D

| Feature | API 607 | API 6D |

|---|---|---|

| Standard Type | Fire test standard | Product specification |

| Main Focus | Fire safety performance | Pipeline service integrity |

| Valve Types | Quarter-turn valves | Ball, gate, plug, check |

| Fire Test Required | Yes | Optional |

| Typical Applications | Refineries, chemical plants | Oil & gas pipelines |

| Soft Seat Allowed | Yes | Yes |

| Fire-Safe Design | Mandatory | Only if specified |

Case Study: Choosing the Wrong Standard

Case 1 – Refinery Isolation Valve

A customer specified API 6D only. During HAZOP review, the valve failed fire-safety requirements. The solution? Switching to an API 607 fire-safe ball valve from Vcore Valve.

Case 2 – Transmission Pipeline Project

Another client requested API 607 valves for a pipeline. This caused compliance issues with the EPC contractor. We corrected the specification to API 6D with optional fire testing.

Data-Driven Insight

Industry audits show that over 30% of valve tender rejections are caused by incorrect standard selection. Fire testing alone does not guarantee pipeline compliance, and pipeline standards do not automatically ensure fire safety.

Market Trends and Industry Insight

-

Increasing demand for dual-certified API 6D + API 607 valves

-

More EPCs require fire-safe pipeline valves

-

Growing alignment between API and ISO fire standards

-

Emphasis on lifecycle safety rather than initial cost

At Vcore Valve, we see strong growth in customised fire-safe pipeline ball valves for offshore and LNG projects.

Selection Tips from Vcore Valve Engineers

-

High fire risk? Choose API 607

-

Pipeline transmission? API 6D is essential

-

Do both conditions apply? Specify API 6D + API 607

-

Always confirm actuator compatibility after fire testing

-

Don’t assume one standard replaces the other

Conclusion & Call to Action

Understanding API 607 vs API 6D ball valves is not about choosing “the better standard”—it’s about choosing the right one.

At Vcore Valve, we help engineers, EPC contractors, and distributors select valves that meet real operating conditions, not assumptions.

👉 Contact Vcore Valve for technical guidance, drawings, or customised API-certified ball valves.

FAQ

Q1: Is API 607 mandatory for all ball valves?

No. It is only required where fire safety performance is specified.

Q2: Can an API 6D valve also be fire-safe?

Yes, if it has passed API 607 or ISO 10497 fire testing.

Q3: Does API 607 cover pipeline requirements?

No. It only verifies fire performance, not pipeline design.

Q4: Which standard is more expensive?

API 607 valves may cost more due to fire testing, but API 6D valves often involve stricter manufacturing controls.

Q5: Does Vcore Valve supply both standards?

Yes. We manufacture API 607, API 6D, and dual-certified ball valves.

References

-

American Petroleum Institute (API)

API 607 – Fire Test for Quarter-turn Valves and Valves Equipped with Non-metallic Seats

Official standard defining fire testing requirements for soft-seated quarter-turn valves used in fire-risk applications. -

American Petroleum Institute (API)

API 6D – Specification for Pipeline and Piping Valves

Industry-recognised specification covering design, materials, testing, and inspection requirements for pipeline valves in oil and gas transmission systems. -

International Organization for Standardization (ISO)

ISO 10497 – Testing of valves — Fire type-testing requirements

International fire test standard commonly referenced alongside API 607 for validating fire-safe valve performance. -

Oil & Gas UK – Engineering Guidelines

Valve Selection Criteria for Hydrocarbon Processing Facilities

Guidance on selecting valves based on service conditions, fire risk, pressure class, and lifecycle safety. -

Pipeline and Gas Journal

Understanding API Valve Standards in Transmission Systems

Industry analysis discussing practical differences between fire-tested valves and pipeline-qualified valves. -

Vcore Valve – Technical Engineering Notes

Internal Design and Testing Practices for API 607 and API 6D Ball Valves

Based on manufacturing experience, fire testing records, and project delivery for refinery and pipeline applications.