🔹 Quick Summary

Sluice valve vs gate valve is often discussed due to their similar appearance and linear shut-off mechanism. However, their internal structure, application focus, and performance characteristics differ significantly. Choosing the wrong valve can lead to leakage, blockage, excessive wear, or even system failure. In this guide, Vcore Valve explains the real engineering differences between sluice valves and gate valves, helping engineers, contractors, and procurement teams make confident, application-driven decisions.

🔹 Opening Scenario: A Common Site Mistake

“Both are gate-type valves, so they should work the same, right?”

This is a sentence we hear surprisingly often during project reviews. In one municipal wastewater project, a standard gate valve was installed where a sluice valve was required. Within six months, sediment buildup prevented full closure, leading to leakage and emergency replacement.

Understanding the difference is not academic—it’s practical, costly, and critical.

🔹 User Pain Points

Confusing Similar Appearance

Both valves look almost identical externally, leading to incorrect substitutions during procurement.

Premature Failure in Harsh Media

Gate valves struggle in slurry or debris-laden flow, resulting in jamming or seat damage.

Higher Maintenance Costs

Wrong valve selection increases downtime, cleaning frequency, and spare part consumption.

🔹 Solutions & Expert Recommendations

Match Valve Type to Media Characteristics

Clean fluid? Gate valve.

Slurry or wastewater? Sluice valve.

Consider Long-Term Operation, Not Just Initial Cost

Sluice valves often last longer in harsh service despite higher upfront cost.

Work with a Manufacturer That Understands Application Engineering

At Vcore Valve, we evaluate pressure, media, temperature, and installation orientation before recommending a valve design.

🔹 Structural Differences: Sluice Valve vs Gate Valve

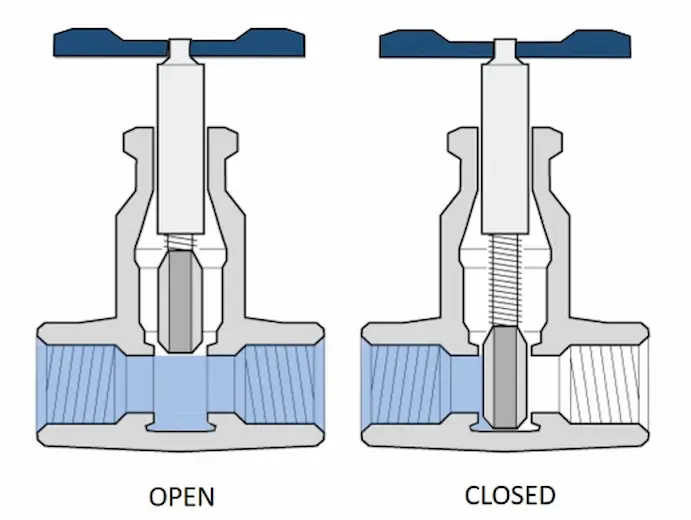

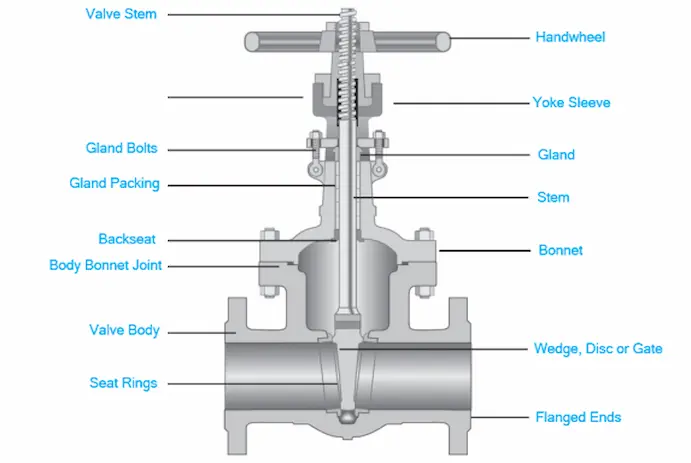

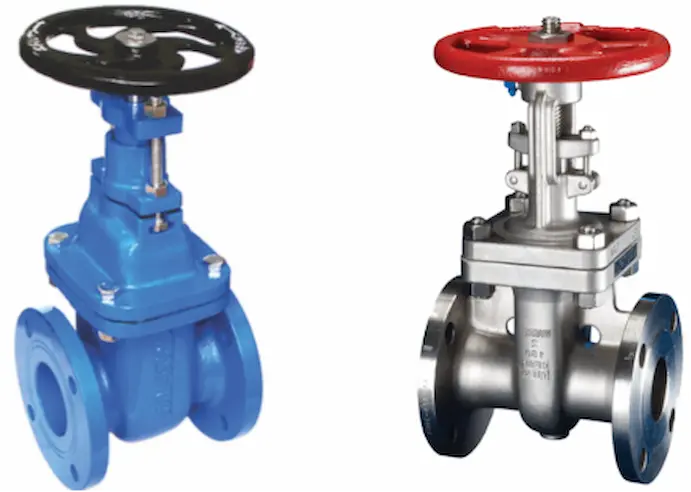

Gate Valve Design Explained

Gate valves use a flat or wedge-shaped gate that moves vertically to block flow. The sealing relies heavily on precise seat contact, making them ideal for clean liquids and gases.

Limitations:

-

Sensitive to debris

-

Prone to jamming

-

Not suitable for throttling

Sluice Valve Design Explained

Sluice valves are engineered specifically for solids-bearing or viscous media. Their gate often features a sharpened or knife-edged design capable of cutting through slurry and sediment.

Advantages:

-

Self-cleaning action

-

Reduced blockage risk

-

Better sealing in dirty media

🔹 Technical Comparison Table

| Feature | Sluice Valve | Gate Valve |

|---|---|---|

| Flow Media | Slurry, wastewater | Clean liquids, gases |

| Gate Design | Knife / cutting edge | Flat or wedge gate |

| Resistance to Debris | Excellent | Poor |

| Maintenance Frequency | Low in harsh media | High in slurry |

| Typical Industries | Mining, sewage, pulp | Water, oil, steam |

🔹 Case Study Examples

Case 1: Wastewater Treatment Plant

A European treatment facility replaced traditional gate valves with sluice valves on sludge lines. Result:

-

40% reduction in valve-related downtime

-

Zero jamming incidents over 18 months

Case 2: Industrial Cooling Water System

Gate valves remained the preferred choice due to clean water conditions and lower cost, proving that correct selection matters more than valve type.

🔹 Data & Engineering Analysis

Field data shows that gate valves experience up to 3× higher failure rates when exposed to suspended solids above 2%. Sluice valves, by contrast, maintain sealing integrity even at higher solid concentrations due to their cutting action and seat geometry.

🔹 Market & Industry Trends

-

Increasing wastewater recycling projects

-

Growing mining and slurry transport infrastructure

-

Shift towards application-specific valve design

These trends are driving higher demand for sluice valves, particularly in Asia-Pacific and Middle Eastern markets.

🔹 Usage & Selection Tips from Vcore Valve

-

Always confirm media composition

-

Check installation orientation

-

Consider actuator requirements

-

Request material compatibility verification

Our engineering team regularly customises sluice and gate valves for OEM and EPC projects worldwide.

🔹 Conclusion & CTA

Choosing between a sluice valve and a gate valve is not about preference—it’s about application reality. Understanding flow media, maintenance expectations, and operating conditions is essential.

📩 Contact Vcore Valve for expert valve selection support, customised designs, and reliable industrial valve solutions.

🔹 FAQ

Q1: What is the main difference between sluice and gate valves?

Sluice valves are designed for slurry and solids, while gate valves suit clean media.

Q2: Can a gate valve replace a sluice valve?

Not recommended in applications with debris or suspended solids.

Q3: Are sluice valves more expensive?

Yes, but they reduce long-term maintenance costs.

Q4: Do both valves allow full bore flow?

Yes, when fully open.

Q5: Does Vcore Valve supply both types?

Yes, with full customisation options.

🔹 Reference

-

ISO 10434 Industrial Valves – Gate Valves

-

Hydraulic Institute Engineering Data

-

Vcore Valve Internal Application Engineering Guidelines