Quick Overview

Lug butterfly valves are widely used in industrial piping systems thanks to their compact design and end-of-line capability. However, many valve failures blamed on “poor quality” are actually caused by incorrect installation practices. From misalignment to improper bolt tightening, these mistakes can lead to leakage, seat damage, or premature valve failure. Drawing on real installation feedback and field experience, Vcore Valve outlines the most common lug butterfly valve installation mistakes—and how to avoid them.

A Typical On-Site Scenario

“The valve passed factory testing, but it leaks after installation.”

This situation is far more common than most engineers would like to admit. In nearly every case, the root cause is not the valve itself, but how it was installed. Lug butterfly valves are mechanically forgiving—but only within design limits.

Key User Pain Points

Leakage immediately after installation

Even brand-new valves may leak if flange alignment or bolt torque is incorrect.

Seat damage during commissioning

Improper disc positioning can permanently deform resilient seats before the system even starts.

Unexpected difficulty during maintenance

Incorrect installation can make future valve removal or servicing unnecessarily complex.

Practical Solutions from Vcore Valve

Follow valve-specific installation procedures

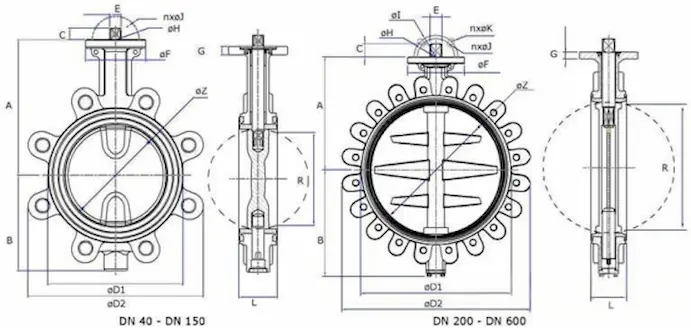

Lug butterfly valves are not installed the same way as wafer valves. Understanding these differences is critical.

Control torque and alignment precisely

Over-tightening bolts or forcing alignment can distort the valve body or seat.

Involve the valve manufacturer early

Application-specific guidance often prevents costly on-site corrections.

The Most Common Lug Butterfly Valve Installation Mistakes

Installing the valve with the disc fully closed

This is one of the most frequent errors. Installing a lug butterfly valve with the disc fully closed increases the risk of disc-to-seat damage during flange tightening. The disc should be slightly open to protect the sealing surface.

Misalignment between pipeline flanges

Even small flange misalignments can cause uneven loading on the valve body, leading to leakage or disc binding. Proper flange parallelism is essential for reliable operation.

Incorrect bolt tightening sequence

Uneven or excessive bolt torque can deform the valve body or compress the seat unevenly. A cross-tightening pattern with controlled torque is always recommended.

Using the valve to correct piping errors

Lug butterfly valves are not designed to compensate for pipe misalignment or piping stress. Forcing the valve into position introduces long-term mechanical stress.

Ignoring end-of-line service limitations

Although lug butterfly valves can be used for end-of-line service, pressure ratings and manufacturer limitations must be respected to avoid seat extrusion or body damage.

Real-World Installation Examples

Case 1: Seat leakage in a water treatment plant

A DN200 lug butterfly valve showed leakage during hydrotesting. Investigation revealed the disc was fully closed during installation, causing seat deformation. Reinstallation with correct disc positioning resolved the issue.

Case 2: Difficult valve operation in an HVAC system

A valve installed to compensate for misaligned piping required excessive operating torque. Correcting flange alignment restored smooth operation and extended valve life.

These cases highlight why installation discipline is just as important as valve quality.

Technical and Mechanical Analysis

Studies of butterfly valve failures show that:

-

Over 50% of early leakage issues originate from installation errors

-

Incorrect bolt torque is a leading cause of seat deformation

-

Proper alignment reduces operating torque by up to 30%

From an engineering perspective, lug butterfly valves rely on even load distribution across the body and seat. Any deviation directly affects sealing performance.

Market and Industry Trends

As systems become more compact and pressures increase, installation tolerance margins shrink. The industry is moving toward:

-

Clearer installation documentation

-

Pre-installation training for contractors

-

Valves with more robust seat designs

-

Digital torque tools for controlled installation

Manufacturers like Vcore Valve increasingly support customers with installation guidance to reduce post-installation disputes.

Installation Style and Best Practices

Always inspect flanges before installation

Position the disc slightly open during fitting

Use calibrated torque tools

Follow a cross-bolt tightening sequence

Verify valve operation before pressurisation

These steps significantly reduce the risk of installation-related failures.

Conclusion and Call to Action

Lug butterfly valve failures are rarely caused by manufacturing defects. In most cases, installation mistakes are the real culprit. By understanding common errors and following proven installation practices, operators can dramatically improve valve performance and service life.

At Vcore Valve, we design lug butterfly valves for durability—but correct installation is what allows that durability to shine. If you need technical guidance or application-specific recommendations, our engineering team is ready to assist.

FAQ

Can lug butterfly valves be used for end-of-line service?

Yes, but only within the pressure and size limits specified by the manufacturer.

Should the valve disc be open or closed during installation?

Slightly open, to protect the seat and disc edges.

Is over-tightening flange bolts a common problem?

Yes. Excessive torque can distort the valve body and damage the seat.

Can a lug butterfly valve compensate for pipe misalignment?

No. Piping must be correctly aligned before installation.

Does Vcore Valve provide installation support?

Yes. Vcore Valve offers technical guidance for proper valve installation and commissioning.

Reference

-

ISO 5211 – Actuator Mounting Standards

-

API 609 – Butterfly Valves

-

MSS SP-67 – Butterfly Valve Installation Practices

-

Manufacturer Installation Guidelines (Industrial Valves)