Quick Summary

Our V-port ball valve is widely recognised as a practical solution where accurate flow control is required but a full control valve may be unnecessary or too costly. At Vcore Valve, we often recommend V-port designs for applications demanding stable modulation, reduced cavitation, and improved controllability. This article breaks down how V-port ball valves work, their advantages, limitations, and how to select the right configuration for real-world industrial use.

Opening Scenario: When Standard Ball Valves Fall Short

“We only need partial flow control—why is the system unstable?”

This is a common question raised during commissioning. A standard ball valve offers excellent shut-off but performs poorly in throttling. That’s exactly where a v port control ball valve steps in, bridging the gap between on/off isolation and precise flow regulation.

Common User Pain Points

Poor Flow Control with Standard Ball Valves

Traditional full-port ball valves lack linear flow characteristics, causing sudden flow changes.

Cavitation and Noise Issues

High-pressure drops across improperly throttled valves often lead to vibration, noise, and erosion.

Over-Specifying Control Valves

Using globe or cage control valves where they’re not required increases both CAPEX and maintenance costs.

Practical Solutions & Expert Recommendations

Use V-Port Geometry for Modulating Service

The V-shaped notch enables gradual flow change and improved control accuracy.

Match V-Angle to Process Requirements

Different V angles (30°, 60°, 90°) directly affect flow characteristics and controllability.

Balance Cost and Performance

A v port ball valve offers a cost-effective alternative to traditional control valves in many systems.

What Is a V-Port Ball Valve?

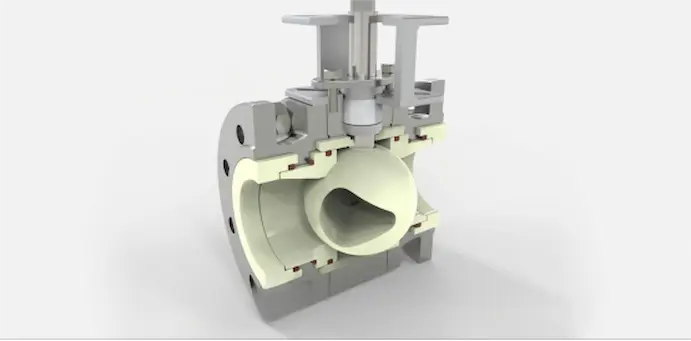

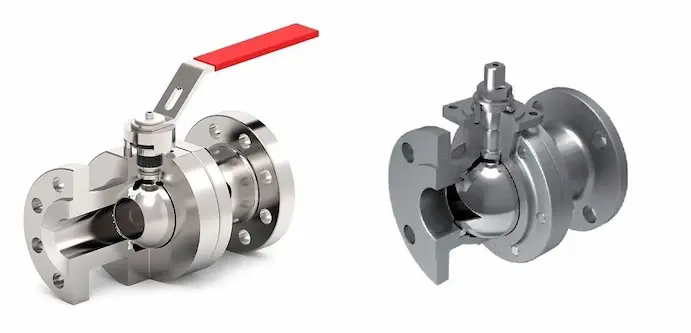

Our v port ball valve features a V-shaped or segmented opening in the ball. As the valve rotates, the opening area changes progressively, enabling controlled flow rather than abrupt on/off action.

Common Design Variants

-

V-notch ball valve

-

Segmented ball valve

-

Characterised control ball valve

Each design targets improved throttling performance compared to conventional ball valves.

Key Advantages of V-Port Ball Valves

Improved Flow Control Accuracy

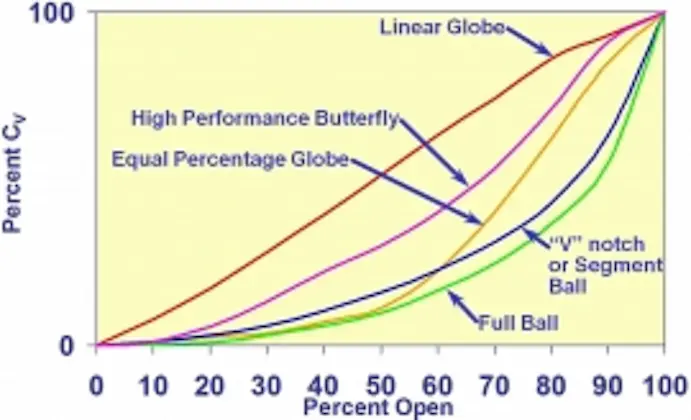

The V-shaped port delivers near-linear or equal-percentage flow characteristics, depending on design.

Reduced Cavitation and Turbulence

Gradual pressure reduction helps minimise cavitation damage and flow-induced vibration.

Compact and Robust Design

Compared with globe valves, v port control ball valves offer smaller size and higher Cv values.

Lower Maintenance Requirements

Fewer internal components mean reduced wear and simpler servicing.

Limitations You Should Be Aware Of

Not Suitable for Ultra-Fine Control

For extremely precise modulation, a dedicated control valve may still be required.

Higher Torque Requirements

The characterised port increases flow forces, often necessitating a stronger actuator.

Seat Wear Under Severe Throttling

Continuous operation at small openings may accelerate seat and ball wear.

Technical Comparison

| Feature | V-Port Ball Valve | Standard Ball Valve | Globe Control Valve |

|---|---|---|---|

| Flow Control | Good | Poor | Excellent |

| Shut-off Performance | Excellent | Excellent | Good |

| Cv Value | High | Very High | Moderate |

| Size & Weight | Compact | Compact | Larger |

| Cost | Medium | Low | High |

| Maintenance | Low | Low | Medium–High |

Case Study: Real-World Applications

Case 1: Chemical Dosing System

A European chemical plant replaced globe valves with segmented v-port ball valves, achieving stable flow control while reducing maintenance costs by over 20%.

Case 2: Steam Control Line

In a medium-pressure steam system, V-port valves significantly reduced noise and valve trim erosion compared to standard ball valves.

Engineering Data & Flow Behaviour Analysis

Testing data from Vcore Valve projects shows:

-

Flow controllability improves by up to 40% compared with full-port ball valves

-

Cavitation damage risk reduced by 30–50% in throttling conditions

-

Actuator torque requirements increase by 15–25%, depending on V angle

These figures highlight why proper sizing and actuator selection are essential.

Market Trends & Industry Insights

-

Growing demand for v port ball valves in water treatment and chemical processing

-

Increasing use in automated systems with electric and pneumatic actuators

-

Preference for segmented ball designs in slurry and fibre-laden media

Vcore Valve continues to optimise seat materials and port geometry to meet these evolving needs.

Selection Tips from Vcore Valve Engineers

-

Choose 30° or 60° V-ports for finer control

-

Avoid continuous throttling at very small openings

-

Always size the actuator with sufficient safety margin

-

Consider characterised trims for demanding applications

Conclusion

A v port ball valve offers an excellent balance between shut-off reliability and flow control capability. When selected correctly, it outperforms standard ball valves and avoids the cost and complexity of traditional control valves. At Vcore Valve, we help clients engineer the right solution—matched to process conditions, media, and lifecycle expectations.

👉 Contact Vcore Valve today for technical support or customised V-port ball valve solutions.

FAQs

What is a V-port ball valve used for?

It is used for applications requiring controlled or modulating flow rather than simple on/off isolation.

How does a V-port ball valve differ from a standard ball valve?

The V-shaped opening allows gradual flow adjustment, while standard ball valves open abruptly.

Is a V-port ball valve a control valve?

It offers control functionality but may not replace a dedicated control valve in high-precision applications.

Does a V-port ball valve require a stronger actuator?

Yes, due to increased flow forces, higher torque actuators are often needed.

Can V-port ball valves handle dirty or slurry media?

Segmented designs perform well, but material and seat selection are critical.

What industries commonly use V-port ball valves?

Chemical processing, water treatment, pulp & paper, power generation, and oil & gas.

Reference

-

JSC Valve – V-Port Ball Valve: Analysis of Advantages and Limitations

-

Emerson – Control Valve Fundamentals

-

Engineering Toolbox – Flow Control Valves Overview