Quick Summary

Discussing soft seat vs metal seat ball valve is one of the most critical topic in valve engineering. Seat design directly affects sealing performance, temperature resistance, service life and overall system reliability. At Vcore Valve, we see more failures caused by incorrect seat selection than by valve body defects. This guide explains the differences clearly and practically.

A Common Engineering Scenario

“Why does the valve leak after six months?”

“It sealed perfectly during pressure testing.”

In most cases, the answer lies not in manufacturing quality, but in ball valve seat design.

Key User Pain Points

Leakage Under Real Operating Conditions

Many valves pass factory tests but fail under temperature fluctuation or media erosion.

Short Service Life

Incorrect seat material accelerates wear, deformation or galling.

Misunderstanding ‘Zero Leakage’

Engineers often expect bubble-tight sealing in conditions where it is physically unrealistic.

Practical Solutions and Selection Advice

Match Seat Material to Temperature and Media

Seat performance is heavily influenced by operating environment.

Understand Sealing Mechanism, Not Just Standards

API or ISO compliance does not guarantee suitability.

Design for the Entire Lifecycle

Maintenance intervals and downtime must be considered.

What Is a Soft Seated Ball Valve?

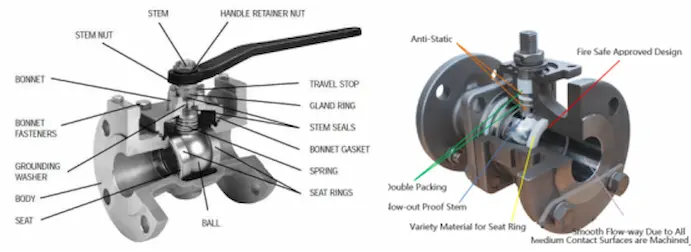

Our soft seated ball valve uses non-metallic materials such as PTFE, RPTFE or PEEK to achieve elastic sealing between the ball and seat.

Key Advantages

-

Excellent bubble-tight sealing

-

Low operating torque

-

Cost-effective

-

Ideal for clean, low-temperature services

What Is a Metal Seated Ball Valve?

Our metal seated ball valve uses metal-to-metal contact, often enhanced by hard coatings such as tungsten carbide or chromium carbide.

Key Advantages

-

High temperature resistance

-

Suitable for abrasive and corrosive media

-

Longer service life in severe conditions

-

Fire-safe capability

Soft Seat vs Metal Seat ball valve: Technical Comparison

| Parameter | Soft Seated Ball Valve | Metal Seated Ball Valve |

|---|---|---|

| Seat material | PTFE, RPTFE, PEEK | Stainless steel, alloy steel |

| Sealing performance | Bubble-tight | Class IV–VI |

| Temperature range | Up to ~200°C | Up to 600°C+ |

| Media tolerance | Clean fluids | Abrasive, corrosive |

| Operating torque | Low | Higher |

| Fire safety | Limited | Excellent |

| Typical applications | Water, gas, chemicals | Slurry, steam, oil |

Engineering Performance Analysis

Sealing Behaviour

Soft seats rely on elastic deformation, while metal seats depend on precision machining and surface hardness.

Wear Resistance

Metal seats outperform soft seats in particulate-laden media by several magnitudes.

Thermal Stability

Soft seats lose elasticity at elevated temperatures; metal seats maintain integrity.

Case Study: Refinery High-Temperature Line

A refinery initially used soft seated ball valves for thermal oil service at 280°C. Seat deformation caused leakage within months.

After switching to metal seated ball valves from Vcore Valve, the system achieved:

-

Zero unplanned shutdowns

-

Stable torque over 3 years

-

Improved fire safety compliance

Data-Based Comparison

Industry data indicates:

-

Over 65% of soft seat failures are temperature-related

-

Metal seated valves last 3–5 times longer in abrasive services

-

Soft seats dominate general process industries, while metal seats rule severe service

Industry Trends and Market Insights

-

Increasing use of metal seated ball valves in energy and mining sectors

-

Advanced coatings improving metal seat sealing performance

-

Hybrid designs combining soft backup seals with metal seats

At Vcore Valve, demand for metal seated solutions has grown steadily in high-risk applications.

Selection and Usage Recommendations

Choose a soft seated ball valve if you need:

-

Bubble-tight shut-off

-

Low torque automation

-

Clean, stable media

-

Cost efficiency

Choose a metal seated ball valve if you require:

-

High temperature resistance

-

Abrasive or corrosive media handling

-

Fire-safe operation

-

Long service life

Conclusion

There is no universally “better” ball valve seat—only a correctly engineered one.

At Vcore Valve, we design both soft and metal seated ball valves based on real operating conditions, not assumptions.

👉 Contact Vcore Valve for expert seat selection and severe service valve solutions.

FAQs

Q1: Are metal seated ball valves leak-proof?

They offer excellent sealing but usually not bubble-tight.

Q2: Why do soft seats fail at high temperature?

Loss of elasticity leads to deformation and leakage.

Q3: Can metal seated valves be used for throttling?

Yes, if specifically designed for control service.

Q4: Are metal seats always more expensive?

Initial cost is higher, but lifecycle cost is often lower.

Q5: What seat material does Vcore Valve recommend for slurry?

Metal seats with hard coating are preferred.

Q6: Can soft seats be fire-safe?

Only when combined with secondary metal seals.

Reference

-

NSW Valve. Ball Valve Seat Designs Explained: Soft vs Metal Seat.

-

API 6D. Specification for Pipeline Valves.

-

ISO 17292. Metal Ball Valves for Petroleum Industries.

-

Vcore Valve Technical Notes. Ball Valve Sealing Technologies.