Quick Summary

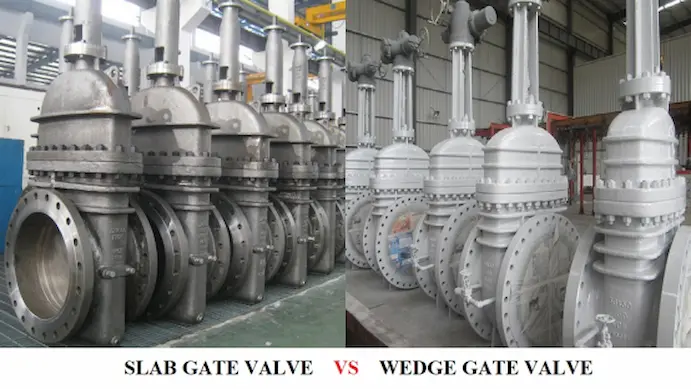

Discussing wedge gate valve vs slab gate valve is not just a matter of preference—it directly affects sealing reliability, maintenance cost and system uptime. At Vcore Valve, we see this decision made incorrectly far too often. This guide breaks down the real engineering differences to help you select the right solution with confidence.

A Familiar Engineering Conversation

“The line is leaking again.”

“Did we use a wedge gate valve?”

“Yes… same as last project.”

“But this is slurry service—why not slab?”

If that exchange feels uncomfortably familiar, you’re not alone.

Common User Pain Points

Incorrect Valve Selection

Many systems use wedge gate valves by default, even when conditions clearly favour a slab gate valve.

Unexpected Leakage

Improper sealing design can lead to internal leakage, especially in dirty or high-cycle services.

High Maintenance Costs

Valves that are hard to clean, repair or re-seat quickly become liabilities rather than assets.

Practical Solutions and Selection Advice

Match Valve Type to Media

Clean fluids? A wedge gate valve often performs well. Slurry, gas, or piggable pipelines? Slab gate valves excel.

Consider Operating Frequency

Frequent cycling increases wear on wedge seats, while slab designs maintain stable sealing.

Think Beyond Initial Cost

A cheaper valve upfront may cost far more over its service life.

Case Examples from the Field

Case 1: Water Treatment Plant

A municipal project used wedge gate valves for clean water isolation. Result: low cost, minimal maintenance, excellent service life.

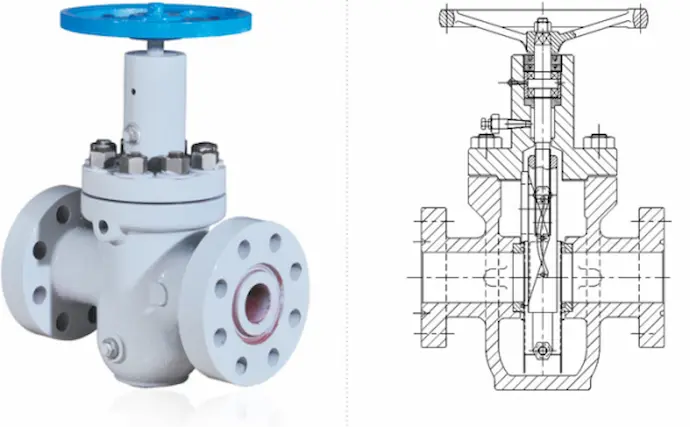

Case 2: Gas Transmission Pipeline

An oil & gas client replaced wedge valves with slab gate valves to support pigging operations. Leakage incidents dropped to zero.

Technical Comparison: Wedge Gate Valve vs Slab Gate Valve

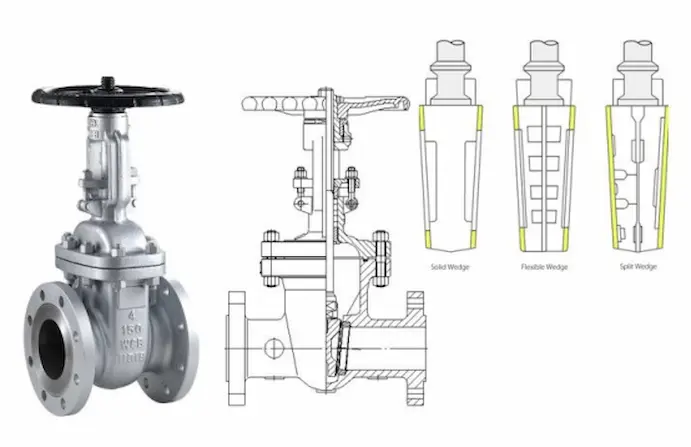

| Parameter | Wedge Gate Valve | Slab Gate Valve | Engineering Impact |

|---|---|---|---|

| Gate Design | Solid or flexible wedge | Flat slab with through-conduit | Affects sealing and flow |

| Sealing Method | Wedging force against seats | Parallel seats with slab | Slab offers more stable sealing |

| Flow Path | Partially obstructed | Full bore | Slab supports pigging |

| Media Suitability | Clean liquids | Gas, slurry, dirty media | Prevents debris buildup |

| Maintenance | Moderate | Low | Slab easier to clean |

| Bidirectional Sealing | Limited | Excellent | Critical for pipelines |

| Typical Standards | API 600 | API 6D | Defines application scope |

Data-Driven Insights

-

Slab gate valves reduce pressure drop by up to 15–20% in long pipelines

-

Wedge gate valves show higher seat wear after 5,000+ cycles

-

Through-conduit designs significantly lower pigging risks

Market Trends and Industry Insight

The global shift toward pipeline efficiency and predictive maintenance is driving increased adoption of slab gate valves, particularly in oil, gas and LNG sectors. Meanwhile, wedge gate valves remain dominant in water, HVAC and general industrial services.

Style and Usage Recommendations

-

Choose wedge gate valves for cost-sensitive, clean-flow systems

-

Choose slab gate valves for critical isolation and piggable pipelines

-

Always align valve choice with long-term operational goals

Conclusion

There is no “one-size-fits-all” answer—but there is a correct one for your system. At Vcore Valve, we help engineers select valves that reduce downtime, cut maintenance costs and extend service life.

👉 Talk to our technical team or explore our full range of industrial gate valves today.

FAQ

Q1: What is the main difference between a wedge gate valve and a slab gate valve?

The wedge gate valve seals by mechanical wedging, while the slab gate valve uses parallel seats and a through-conduit design.

Q2: Which valve is better for pigging systems?

Slab gate valves are ideal due to their full-bore, unobstructed flow path.

Q3: Are wedge gate valves cheaper?

Yes, generally lower in initial cost, but may have higher lifecycle costs.

Q4: Can slab gate valves handle dirty media?

Absolutely. They are specifically designed for slurry and gas services.

Q5: Which valve lasts longer?

In harsh or high-cycle conditions, slab gate valves typically outperform wedge designs.

Reference

-

API 600 – Steel Gate Valves

-

API 6D – Pipeline Valves

-

ISO 10434 – Bolted Bonnet Gate Valves

-

ASME B16.34 – Valve Pressure Ratings

-

Union Valve Technical Knowledge Base