Quick Summary

Knowing when a valve is open or closed is crucial for efficient system operation, whether it’s in plumbing, industrial applications, or HVAC systems. At Vcore Valve, we provide industry-leading valves that help professionals optimise system performance and avoid costly downtime. In this guide, we explain how to determine when a valve is fully open or closed, highlighting key valve types and their operations.

Opening Scenario: A Common Dilemma

Picture this: You’re overseeing a critical industrial operation. The pressure gauge is fluctuating, and you’re unsure whether the valve is fully open or closed. Misjudging the position could lead to serious issues like pressure loss, system inefficiency, or even damage to sensitive equipment. How can you ensure you’re operating your valves correctly?

User Pain Points

Valve Mispositioning Risks System Efficiency

Incorrectly identifying whether a valve is open or closed can cause system inefficiency, pressure fluctuations, and, in some cases, system failure.

Difficulty in Manual Valve Operation

In systems with manual valves, it’s not always easy to discern whether the valve is fully open or closed, particularly in remote or hard-to-access areas.

Inadequate Valve Maintenance

Regular maintenance is critical to ensure that valves operate smoothly. Over time, valves may not fully open or close due to wear and tear, making the process even more difficult.

Solutions & Expert Recommendations

Use Visual Indicators or Valve Positioners

To avoid confusion, consider valves with visual position indicators. For instance, many ball valves have a handle that points in the direction of the flow when open, and a perpendicular direction when closed.

Install Automated Valve Actuators

Automated valve actuators can eliminate human error by providing precise control over valve positioning. These actuators often feature indicators that show whether the valve is open or closed.

Regular Valve Inspections and Maintenance

Perform regular inspections to ensure valves are not malfunctioning due to wear. Lubricating moving parts and replacing seals will help maintain the correct operation of the valve over time.

Case Studies from Vcore Valve

Case 1 – Industrial Steam System

In a recent project, Vcore Valve helped a large industrial plant replace manual globe valves with automated ball valves in their steam system. The automation provided clear valve position feedback, leading to more precise pressure control and better system efficiency.

Case 2 – Residential Plumbing

A residential plumbing system using gate valves faced inconsistent water flow due to misjudged valve positioning. After installing valves with visual indicators, the homeowners were able to quickly identify whether the valves were open or closed, improving both efficiency and convenience.

Data & Technical Comparison

| Valve Type | Operation | Key Feature | Common Applications |

|---|---|---|---|

| Ball Valve | Quarter-turn | Easy open/close, low pressure drop | Plumbing, HVAC |

| Gate Valve | Linear | Full bore, ideal for isolation | Water supply |

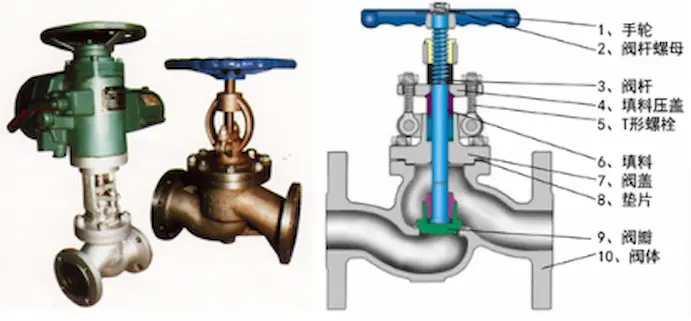

| Globe Valve | Throttling | Precise flow control, higher pressure drop | Heating systems |

| Check Valve | Automatic | Prevents backflow, self-activating | Pumps, HVAC systems |

Market Trends & Industry Insights

-

Increasing Demand for Automated Valve Systems: With increasing automation in industrial processes, valves with actuators and positioners are becoming more popular to provide accurate control over flow and reduce human error.

-

Smart Valves for Remote Monitoring: The rise of Industry 4.0 has made remote monitoring of valve positions essential. Many new valves come with integrated sensors that send real-time data to central systems.

Style/Usage Tips

-

Ball Valves for Quick Operation: Choose ball valves for applications that require frequent on/off operation, such as in plumbing or HVAC systems.

-

Globe Valves for Precision Flow Control: When precision is required for throttling, globe valves are the best choice. They’re often used in heating and cooling systems where consistent flow is critical.

-

Use Check Valves in Preventative Applications: Always use check valves when preventing backflow is crucial, especially in systems with pumps or water pipelines.

Conclusion

Understanding when your valve is open or closed is essential for maintaining system efficiency, preventing damage, and ensuring safe operation. Whether you are in the industrial, HVAC, or residential sectors, Vcore Valve offers reliable and precise solutions for all your valve needs.

👉 Contact Vcore Valve today for expert advice on valve selection, installation, and maintenance. Our team is here to help you choose the right valve for your system, ensuring smooth and efficient operation.

FAQ

Q1: How can I determine if a valve is fully open?

A: Most valves feature a visual indicator. For example, ball valves will have a handle parallel to the flow direction when fully open. Alternatively, valve actuators often have position sensors that provide feedback.

Q2: Can I use a gate valve for throttling?

A: Gate valves are generally not recommended for throttling as they tend to wear out quickly. Globe valves are a better option for precise flow control.

Q3: How do I know when a valve is completely closed?

A: When a valve is closed, the handle or actuator will be in a perpendicular position to the flow direction, ensuring a tight seal.

Q4: Are automated valves more reliable than manual ones?

A: Automated valves, especially those with positioners, offer more reliable and accurate control compared to manual valves. They also reduce the risk of human error.

Q5: Can I install a valve without professional help?

A: While some simple installations can be done without professional assistance, it’s best to consult a professional for proper installation, especially for high-pressure or complex systems.